“Top Gun’s” SR-72 Darkstar Hypersonic Jet:

Is it Real? Real Enough

As seen in

The full-scale rolling model was designed by Lockheed Martin Skunk Works, precision built by ADM Works, and featured extensive use of Verisurf’s metrology software.

By David Olson

There has been a lot of talk about the blockbuster movie, “Top Gun: Maverick,” and the featured hypersonic jet, Darkstar, that propels Tom Cruise to the edge of the atmosphere at Mach 10.2. Were special effects used to capture the drama? Of course, but there was also a lot of realism. The Darkstar plane is a model, but just barely. It is a 70-foot-long full-scale rolling model with a 40-foot wingspan. It is based on aerospace design principles, built using carbon fiber, has functional landing gear, and features a realistic cockpit. The Darkstar was designed by Lockheed Martin Skunk Works and precision built by ADM Works in Orange County, Calif. Though the model did not actually fly it was fabricated using aerospace materials and processes, including extensive use of Verisurf Software, Inc.’s metrology software for reverse engineering, inspection, and assembly guidance.

Not only did the unveiling of the Darkstar impress moviegoers, but it also fooled the Chinese government. Based on an interview with Sandbox, producer Jerry Bruckheimer explained: “The Navy told us that a Chinese satellite turned and headed on a different route to photograph that plane, they thought it was real. That’s how real it looks.” The Darkstar model had to look just as real as the F-18s, P-51 Mustang, and everything else in the movie.

The profile of the Darkstar may look familiar as it was designed by Lockheed Martin Skunk Works, the same development division responsible for the legendary SR-71 Blackbird, its forthcoming successor the SR-72, the F-117 Stealth, and the U-2 spy plane. Skunk Works division engineers designed the full-sized Darkstar model to have a structurally sound body and life-like functional cockpit. The aircraft was lowered to make it look even more streamlined.

The Darkstar appears to have similar but different styling notes to the SR-71 Blackbird. Even though it was built at the height of the Cold War and has not flown in more than 17 years, the SR-71 Blackbird still looks very futuristic. The plane has the lines of a spaceship, and it set the record for the fastest air-breathing manned aircraft in 1976 — a record that remains to this day. So, it is no wonder China wanted to take a look at this apparent new design rolling out of a hanger at Naval Air Station China Lake in California.

Building the SR-72 Darkstar

The fabrication of Darkstar was completed by ADM Works in just 14 weeks. The Skunk Works team provided a comprehensive 3D CAD model that included all profile information and intelligent GD&T specifications. From that point, it was up to the fabrication team to bring the model to life. The project was not without challenges. Up close the plane had to look finished. It did not have to fly, but it did have to roll on the functional landing gear. During filming the model was towed on the NAS China Lake airstrip. “We had to use a bit of our own fabrication ingenuity to make sure the model not only looked good but could stand up to the delivery and intended use,” said Javier Valdivieso, president of ADM Works.

The Skunk Works team provided a comprehensive 3D CAD model that included all profile information and intelligent GD&T specifications. From that point, it was up to the fabrication team to bring the model to life.

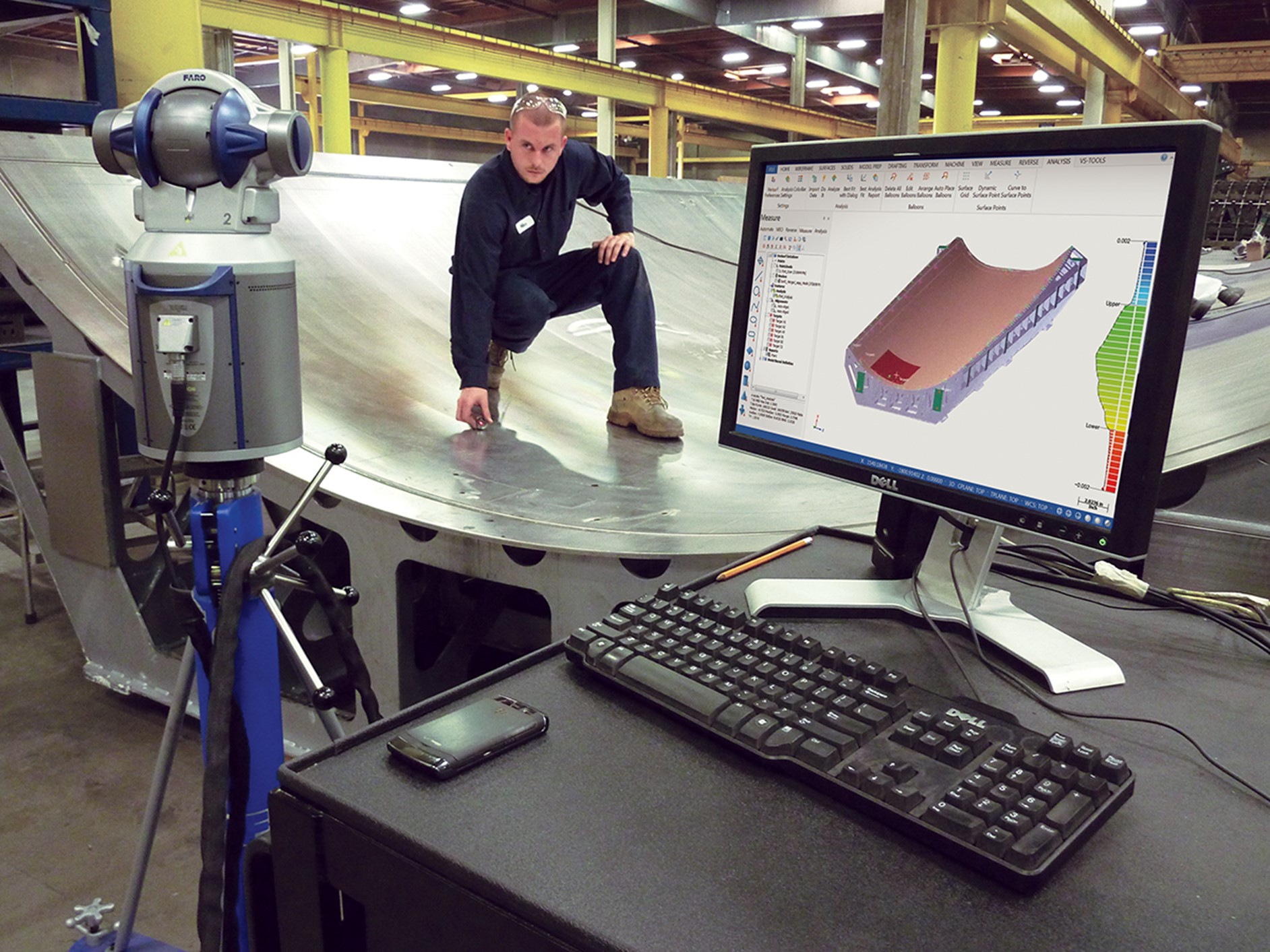

Virtually every aspect of fabricating the Darkstar required the use of precision model-based metrology. This leveraged the 3D CAD model and all its dimensional assets. Verisurf’s software was used in conjunction with digital scanners and laser trackers to accomplish practical reverse engineering tasks, inspection, alignment and assembly guidance.

The fabrication of Darkstar was completed by ADM Works in just 14 weeks. “We had to use a bit of our own fabrication ingenuity to make sure the model not only looked good but could stand up to the delivery and intended use,” said Javier Valdivieso, president of ADM Works (shown here with the finished model).

Verisurf was selected because it is the only inspection and measurement software built on a full-featured 3D CAD platform with intelligent Model-Based Definition. This lets users perform measurement and inspection workflows in a seamless CAD environment and maintains model-based digital continuity. Verisurf’s software is compatible with all CAD file formats, and the Verisurf Device Interface communicates with and drives all fixed and portable CMMs for universal compatibility. “Working through structural design and fabrication challenges with model-based measurements we were able to arrive at practical solutions much more quickly,” Valdivieso said.

Critical Interfaces

The Darkstar needed to be transported from Orange Country to NAS China Lake, a distance of 163 miles over public highways. This required the model to be fabricated in a few pieces that could easily be assembled on set at China Lake. Alignment was critical, basically, the model was built in parts, and then assembled as one. The first time the model was fully assembled was on-site at NAS China Lake. The full assembly was completed in two days, with no modification of seams or interfaces required due to the precision of the design and fabrication at ADM Works.

Layup Molds

The layup molds were designed and created using the supplied CAD profile data. The maximum size of each mold segment is 24’, based on the travel of ADM’s CNC machine. After machining, the surface of each mold was checked using Verisurf scanning, and inspection workflow to verify tolerances, surface finishes, and alignment of the molds. This was critical, especially at the union of the upper and lower sections. Verifying the final surface profile of the assembled molds required millions of individual measurements, collected, processed, and analyzed using Verisurf software.

Engineering of the fabricated Darkstar model was done to accommodate shipping over public highways and final assembly on-site at the filming location at China Lake.

Structural Integrity

The interior bulkheads and wing spars were not included as part of the profile design and needed to be created. These structural elements were designed using a combination of the CAD data and in some cases reverse engineering using Verisurf Reverse. Finished parts were inspected for exact form and fit prior to installation.

Based on the design and placement of the nose gear, there is a 20-foot overhang from the gear to the nose. This required a similar reverse engineering process to account for additional bulkheads and added longerons within the fuselage. Each of the added structural elements used Verisurf Build to create the part and Verisurf Inspection to verify it prior to installation.

Finishing Touches

The design of the Darkstar included a realistic looking and ergonomically correct cockpit, controls dashboard, and canopy lenses, which were precision built from carbon fiber using layup tooling. The tooling was fabricated and then verified against the CAD model using Verisurf. This added an extra element of reality to the overall model.

The design of the Darkstar included a realistic looking and ergonomically correct cockpit, controls dashboard, and canopy lenses, which were precision built from carbon fiber using layup tooling. The tooling was fabricated and then verified against the CAD model using Verisurf. This added an extra element of reality to the overall model.

Verisurf software was used with scanners and trackers to reverse engineer, guide assembly, and inspect virtually every part of the model and tool used to create the Darkstar model.

The cockpit and canopy were designed by reverse engineering comparable examples with Verisurf Reverse, then modifying the overall design to fit the Darkstar.

In the final production the finished cockpit and instrument panel gave a very real perspective to the model.

The Darkstar landing gear was not designed to retract but does support the model, enabling it to be towed behind a vehicle for filming. Verisurf software was used in conjunction with a laser tracker for placements of weldments and overall assembly guidance of the landing gear.

The Darkstar model included functional landing gear which enabled the plane to be towed during filming at Naval Air Weapons Station China Lake in the Mojave Desert.

“The final result goes beyond movie magic, Darkstar viewed close up is hard to distinguish from a flight-ready platform,” Valdivieso said. “At ADM we take pride in exceeding the quality and time expectations of our customers. Advanced metrology platforms, like Verisurf, help us do this by providing practical workflows for inspection, measurement, reverse engineering and tool building.”

ADM Works is a fabrication shop with most of its projects tied to the real aerospace industry, not just movies about it. The company also collaborates with the automotive, architectural, marine, fine art, medical, and yes, the entertainment industries. “We have evolved in our craft over the years becoming competent in many design/build capabilities, including design, engineering, reverse engineering, CAD/CAM, fabrication, prep and paint. Today, we see the greatest productivity gains from the use of model-based measurement and all the practical benefits that extend from this technology,” Valdivieso said.

David Olson is the Director of Sales and Marketing for Verisurf Software, Inc. www.verisurf.com

ADM Works is a fabrication shop with most of its projects tied to the real aerospace industry, not just movies about it. The Company also collaborates with the automotive, architectural, marine, fine art, medical, and yes, the entertainment industries. “We have evolved in our craft over the years becoming competent in many design/build capabilities, including design, engineering, reverse engineering, CAD/CAM, fabrication, prep, and paint. Today, we see the greatest productivity gains from the use of model-based measurement and all the practical benefits that extend from this technology,” said Valdivieso. https://adm-works.com/

Verisurf Software, Inc. is a measurement solutions company committed to delivering advanced surface analysis, quality inspection, assembly guidance, and reverse engineering. Verisurf products and processes are vital to maintaining a digital thread between design, engineering, manufacturing, and finished part validation. Based on a powerful CAD platform, Verisurf is committed to Model-Based Definition (MBD), open standards, and interoperability with all coordinate measuring machines and CAD software. Verisurf solutions help manufacturers produce higher-quality products in less time. www.verisurf.com