Master3DGage®

KEY BENEFITS

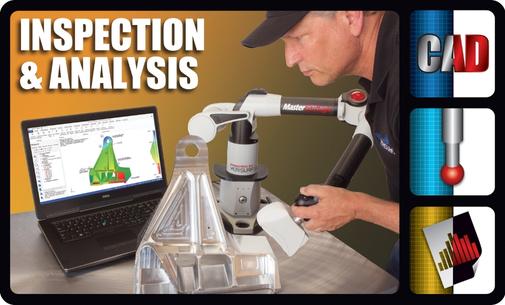

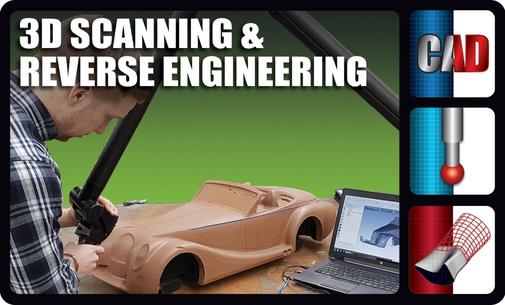

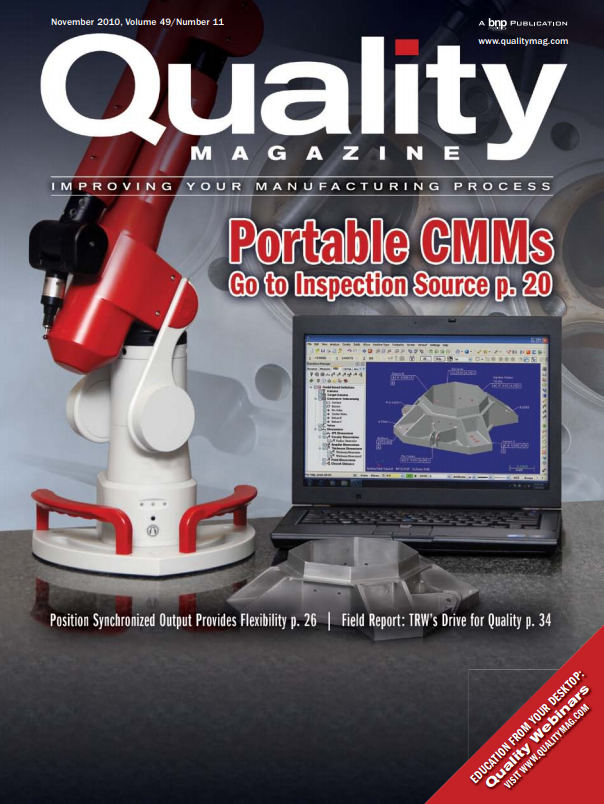

Master3DGage® is a complete CMM hardware and software solution for inspection and reverse engineering. The multi-axis portable CMM features absolute encoders for quick start-up and highly accurate and precise measurements. Its lightweight, wireless design and battery-powered capability enable the Master3DGage® to be placed right into your CNC machine for in-process inspection.

Optional 3D scanner and hot-swappable probes make it easy to switch from scanning complex profiles to probing primitive features in seconds.

Features

Specifications

Calibration Test Standard

ISO 10360-12

Probing size error (PSize)

0.010 mm (0.00039 in)

Probing form error (PForm)

0.018 mm (0.00071 in)

Articulated location error (LDia)

0.021 mm (0.00083 in)

Length measurement error (EUni)

0.024 mm (0.00094 in)

Probing volumetric accuracy

±0.025mm (.00098 in.)

Probing point repeatability

0.014mm (.00055 in.)

Measurement range

1200 mm (4 ft) with absolute encoders

Weight (system with transit case)

12.0 kg/26.45 lb. (35.3 kg/77.82 lb.)

Universal power supply

110-240 VAC, 50/60 Hz

Operating temperature

+5º to +40º C (39º F to 104º F)

Storage temperature

-30° C to 70° C (-22° F to 158° F)

Relative humidity

10% to 90% non-condensing

Transit case size

30.5 x 53.3 x 96.5 cm (12 x 21 x 38 in.)

Shipping details

78.7 x 83.8 x 154.9 cm 68 kg (31 x 33 x61 in. 150 lbs.)

Standard Accessories

Standard Probes

3mm ruby, 6mm ruby, 15mm steel spherical hard probes. Hot swappable, quick-disconnect, automatic probe identification. Includes probe case.

Qualification Sphere

High-chrome high-carbon stainless steel. Calibrate probes and verify accuracy. 25.4 mm diameter and 58 Rc hardness. Certificate and base plate.

Certified Length Bar

Evaluate arm performance against ISO 10360-12, ASME B89.4.22 or VDI/VDE standards. Indicative lengths are 170mm/310mm (6.7″/12.2″)

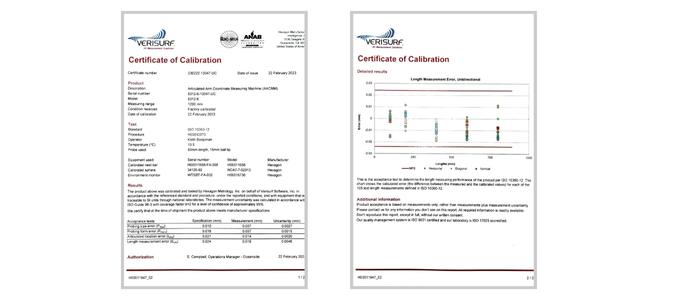

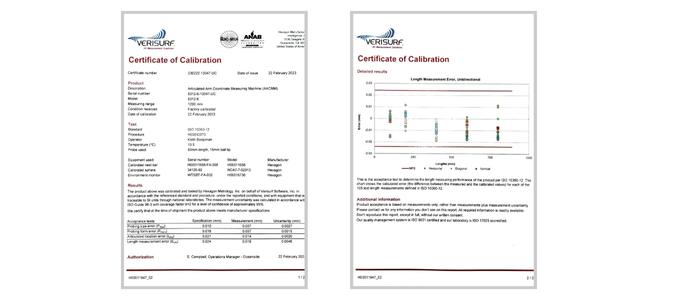

Standard Certificate

Results to the length measurement performance of the product per ISO 10360-12 performed in ISO 9001 quality management system in ISO 17025 certified facility.

Transport Case

Ideal for safely moving your arm around the shop floor or transporting as checked baggage. Includes space for optional laser scanner, probe kits and magnetic mounts.

Optional Accessories

Laser Scanner

High performance laser line scanner with long stand-off distance, integrated range finder, certified calibration sphere, scanner certificate and 1 year warranty.

Probe Kits

Five styli, 10mm long, ruby-ball tips 2/3/4/5/6mm dia, two TKJ adapters, one stylus wrench, one probe wrench.

Short Kit: 50/60/70/85/100mm long

Long Kit: 130/150/180/200mm long

Optional Certificate

Optional ISO 10360-2 acceptance tests for verifying the performance of a coordinate measuring machine (CMM) used for measuring linear dimensions.

Custom Probes

Custom probes for reaching internal cavities and pockets. Includes male TKJ connector and wrench. Specify custom length, probe diameter and silicon nitride or ruby probe material.

Magnet Mounting Kit

Magnetically fix arm to CNC machines and steel tables. Three magnets with force of 100kg, size 50x55x73mm, three screws, SHCS, M8x1.25×20 stainless steel.

Extended Warranties

Multi-year hardware warranties ideal for matching multi-year contracts or multi-year lease periods. Multi-year warranties are discounted saving money over longer periods.

Training Part

Anodized aluminum training part for Verisurf documentation and training courses. Side one has complex profile. Side two has geometric features and pattern.

Software Suites

Performance Engine Builder Package

Reverse engineer, design, build and inspect high-performance engine components.

High Performance Engine Reverse Engineering Video Series Warmup

This package is designed specifically for engine builders who love to win by designing and building the highest accuracy into their motors. The package includes everything you need to start and finish the job.

Master3DGage® News

Master3DGage®