KEY BENEFITS

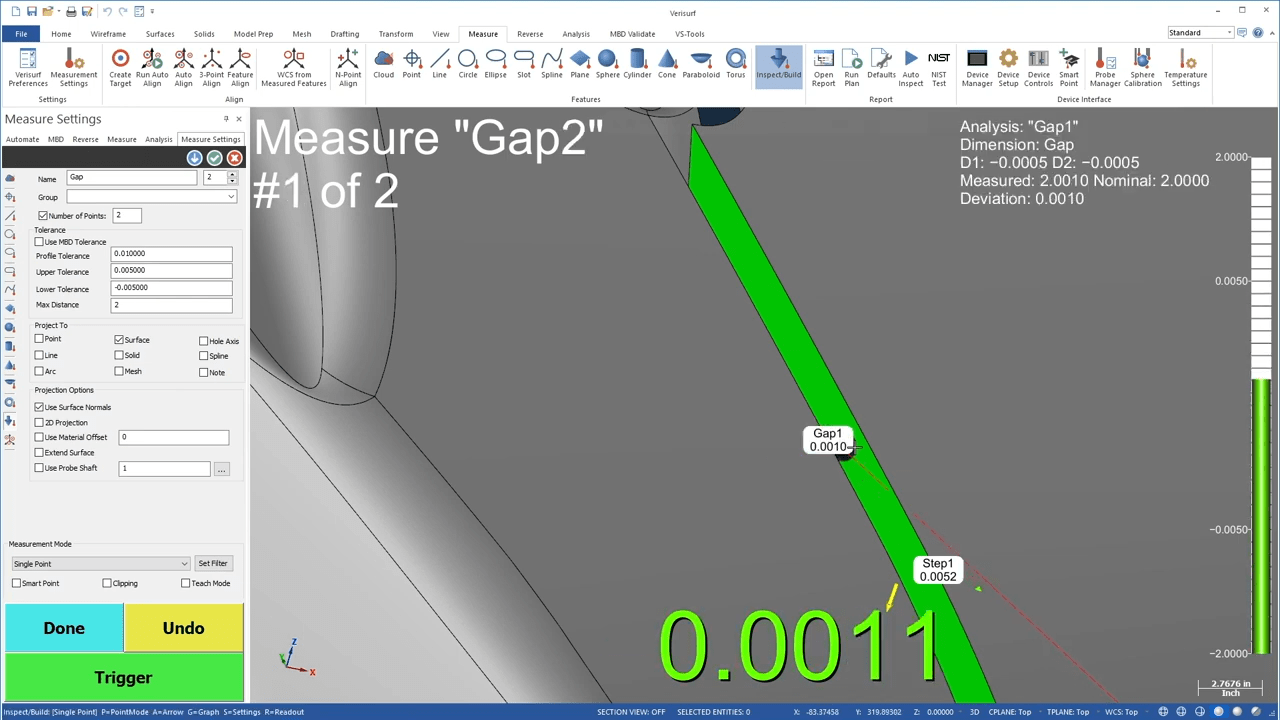

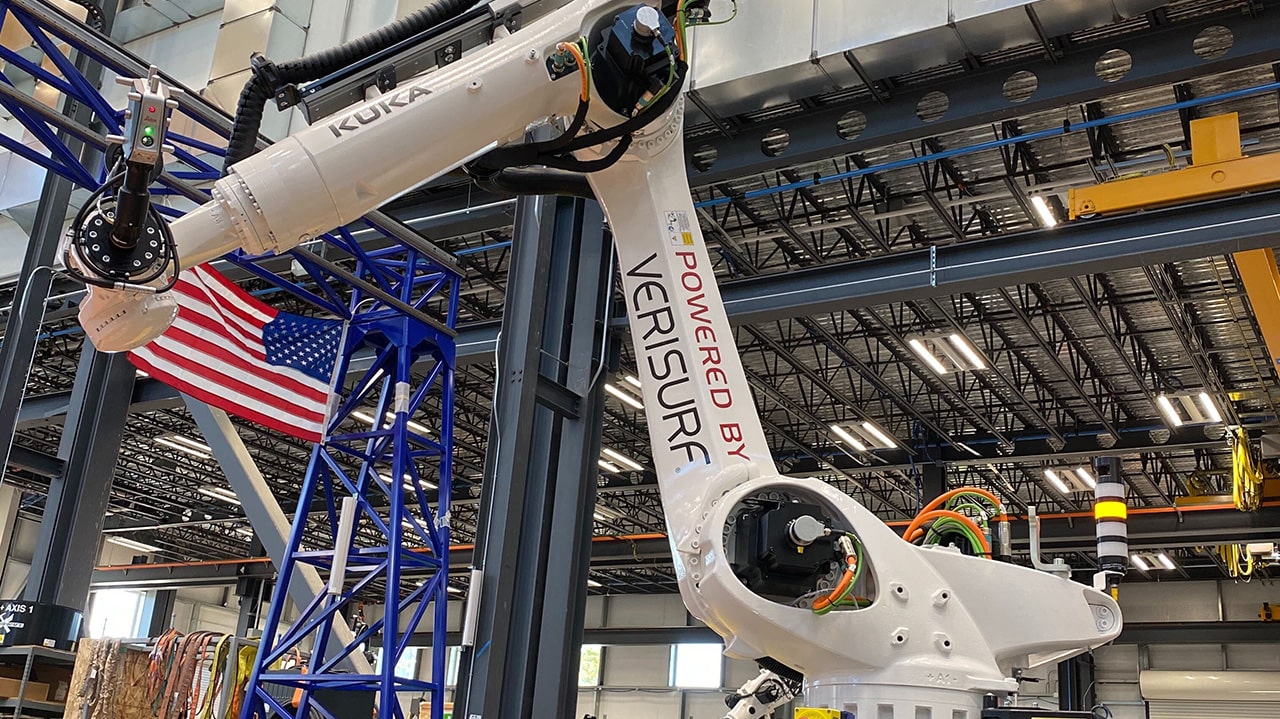

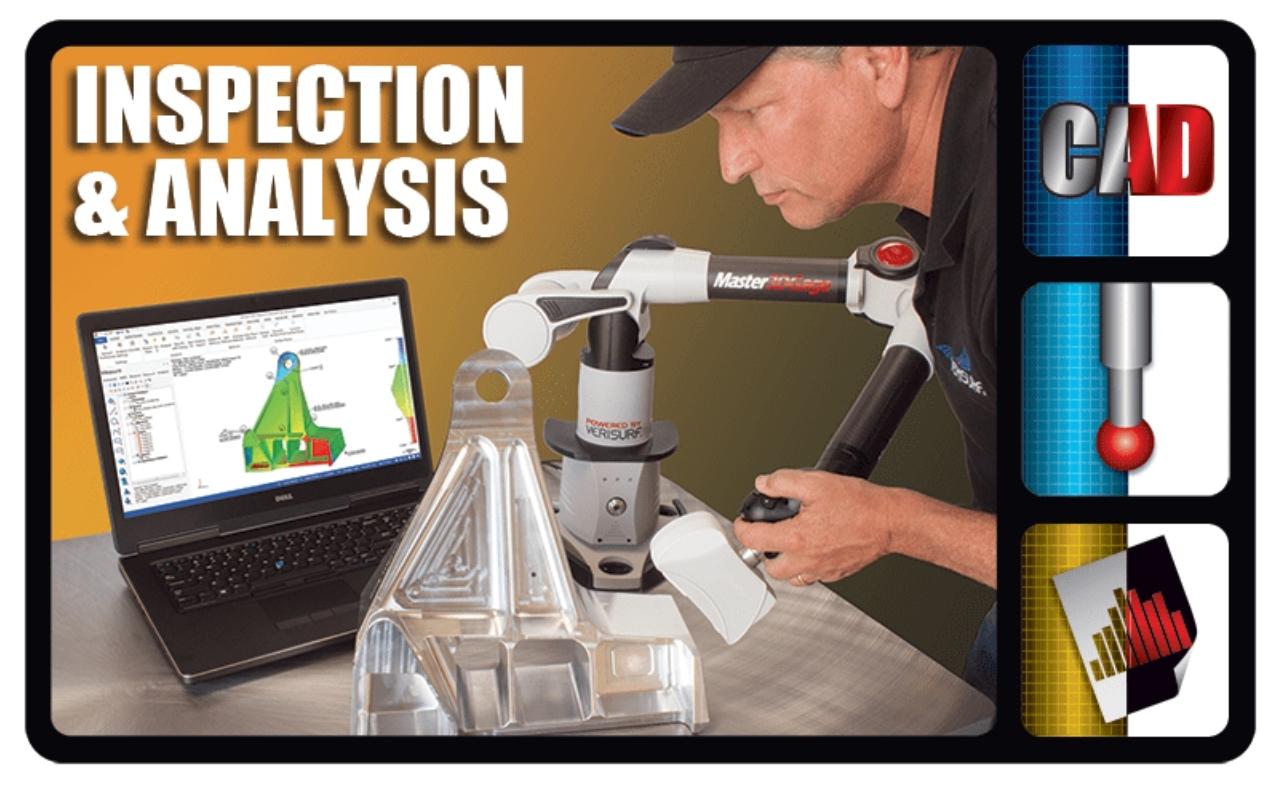

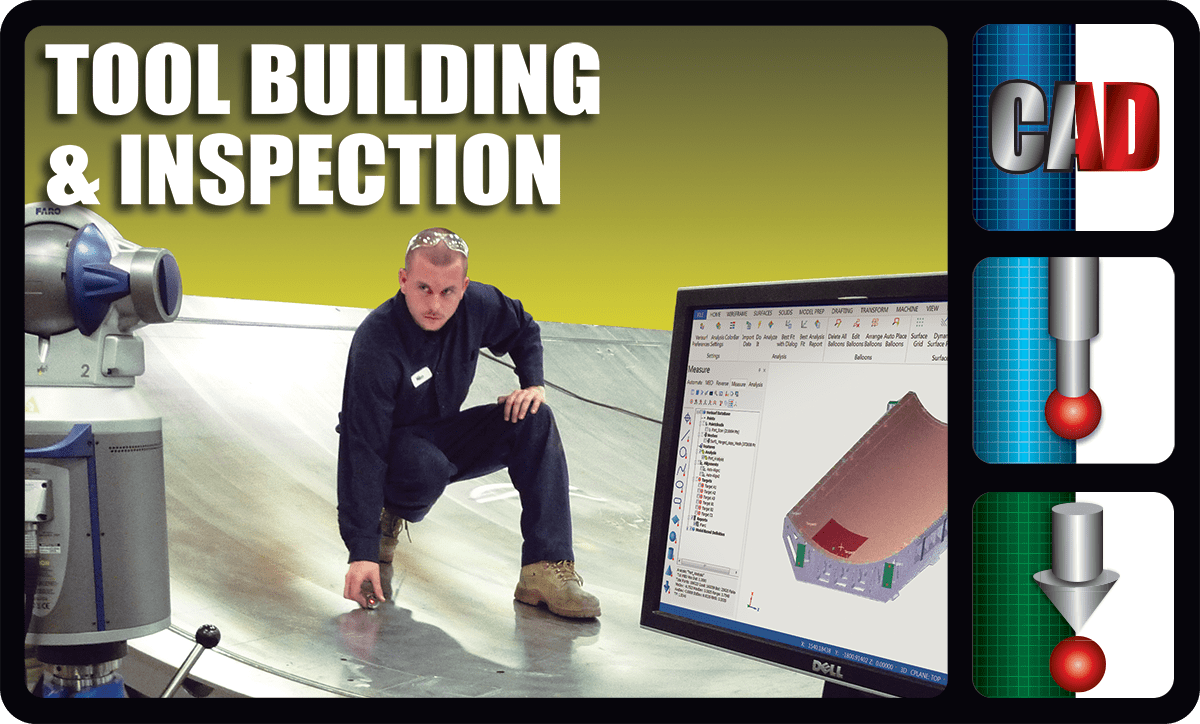

Verisurf BUILD is the industry-leading tool for real-time model-based inspection, tool fabrication, and computer-aided assembly.

Inspect position and profile, set details and fabricate tools, jigs, and fixtures faster and at lower cost than any other process or software.

Evolved and perfected from a large installed base at today’s modern aerospace, automotive, and industrial tooling manufacturers.

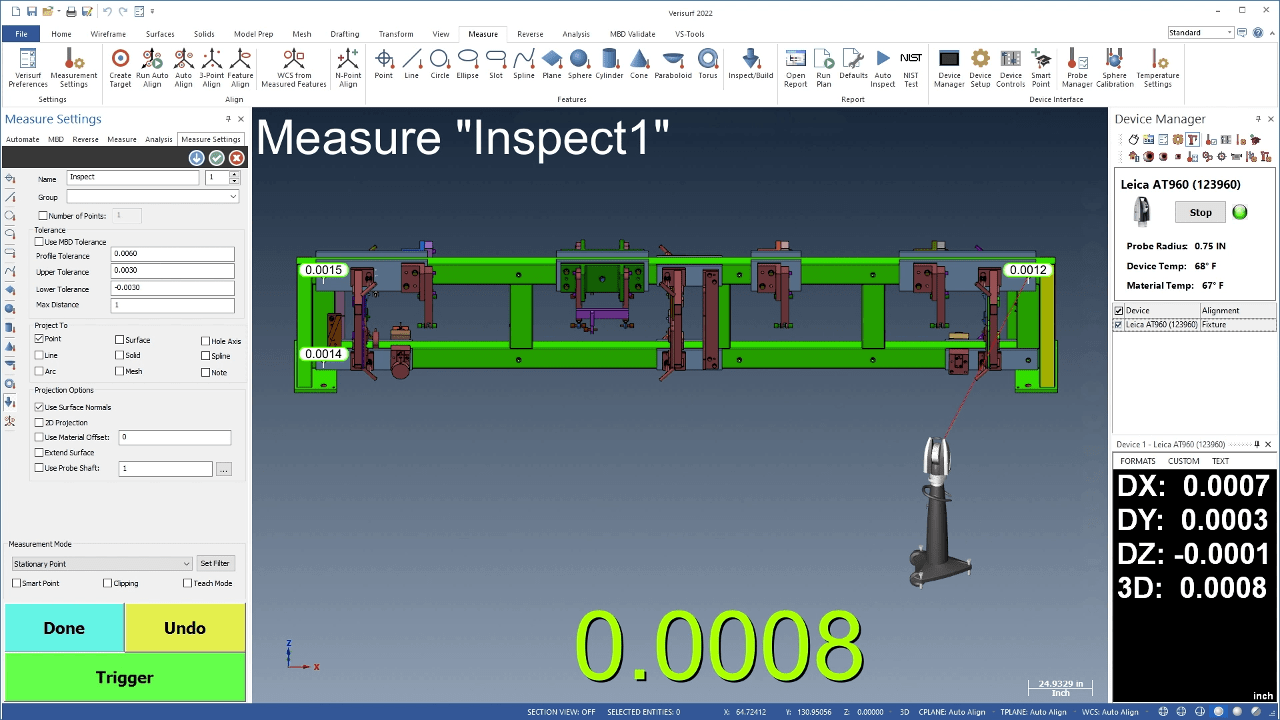

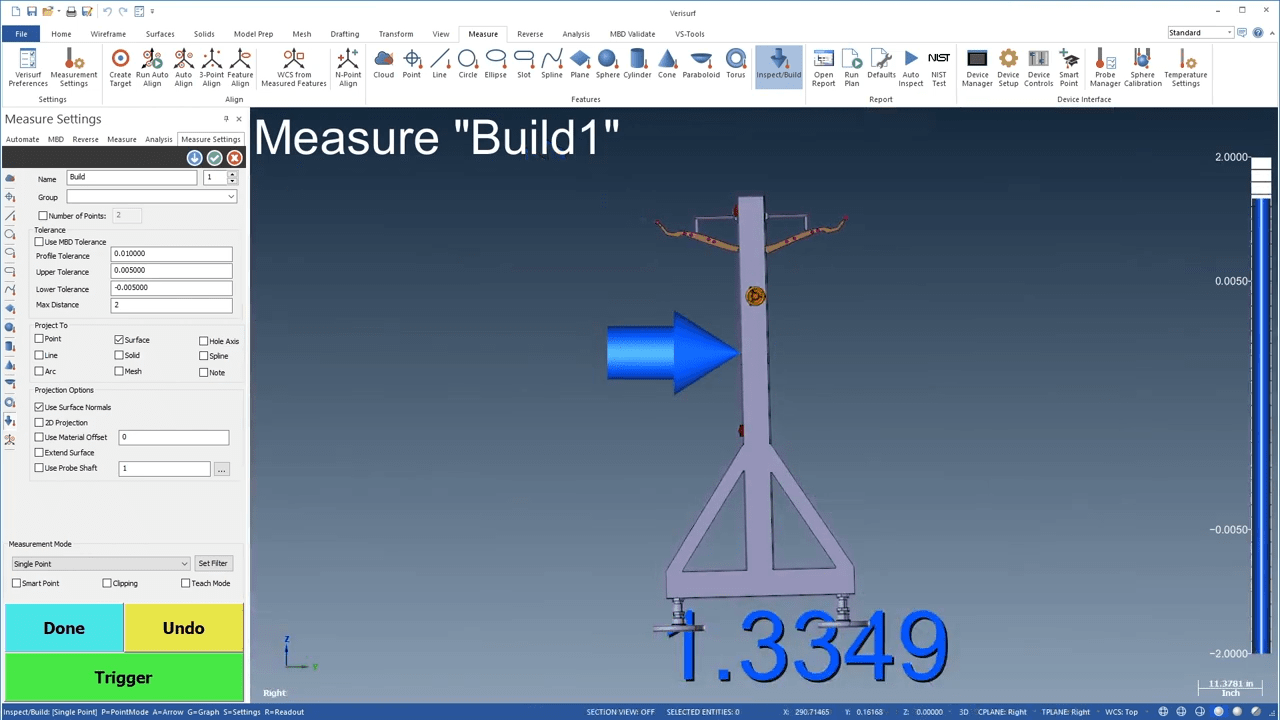

Real-Time Build & Inspection

- Fast and precise inspection, tool fabrication, and computer-aided assembly

- High resolution 3D graphics guide the user with deviation and direction “Build” arrow

- Facilitates part placement by allowing you to indicate parts into position

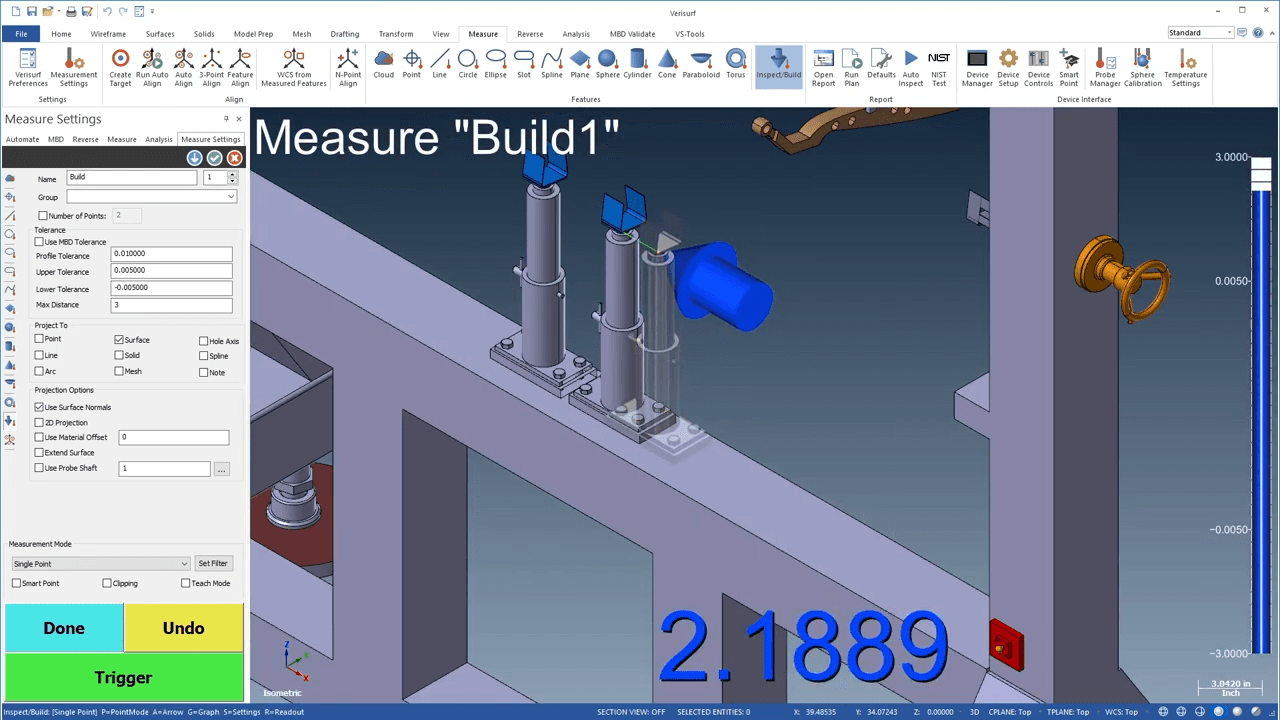

Profile & Position

- Instant read of deviations on common CAD-based measurements, Profile and Position

- CAD-based tolerances are automatically applied to features for both live feedback and report results

- Inspection reports for Profile and Position are just a click away

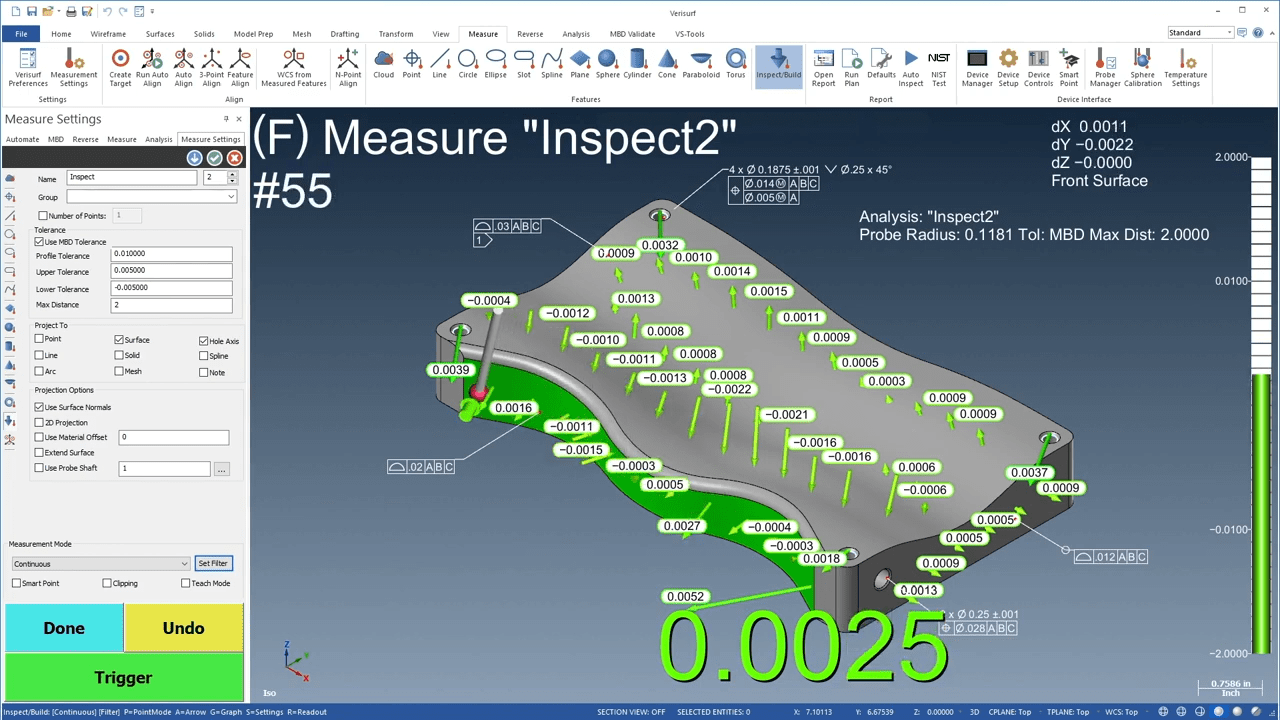

Thickness, Step, Gap, & Flush

- Quick 2-point analysis provides instant display of thickness, step, gap, and flush measurements

- Does not require multi-step setup or “wizards”

Laser Tracker Productivity

- Verify job and environmental variables with Quick Drift Check

- Ensure accuracy for large volume jobs requiring multiple laser locations with Bundling

Industrial Machinery Applications

- Align industrial fixtures and machines to gravity with easy level and plumb features

- Shopfloor checks and validation for squareness, flatness, concentricity, parallelism

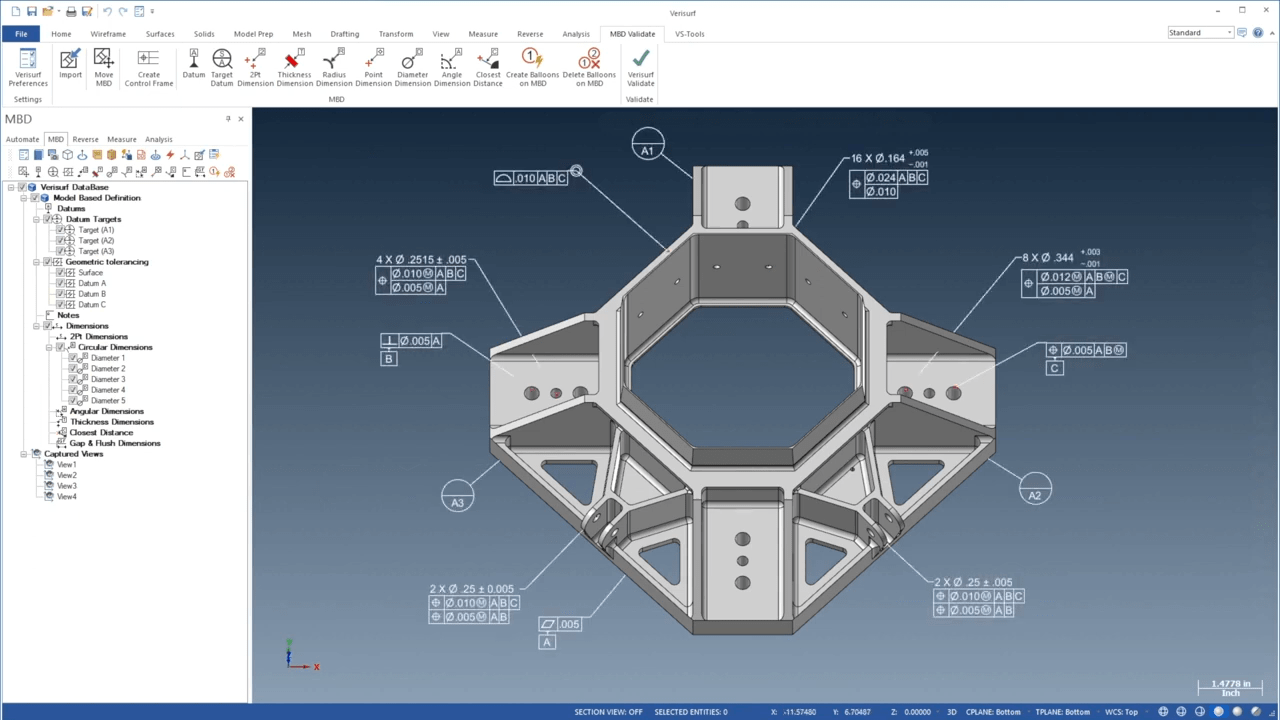

MBD (Model-Based Definition)

- MBD is a powerful set of ISO 10303 & ASME Y14.5 compliant 3D model-feature associated GD&T creation and editing functions

- Can be imported and applied from native CAD PMI that is semantic, including from CATIA, NX, and STEP AP242

Features for Large Applications

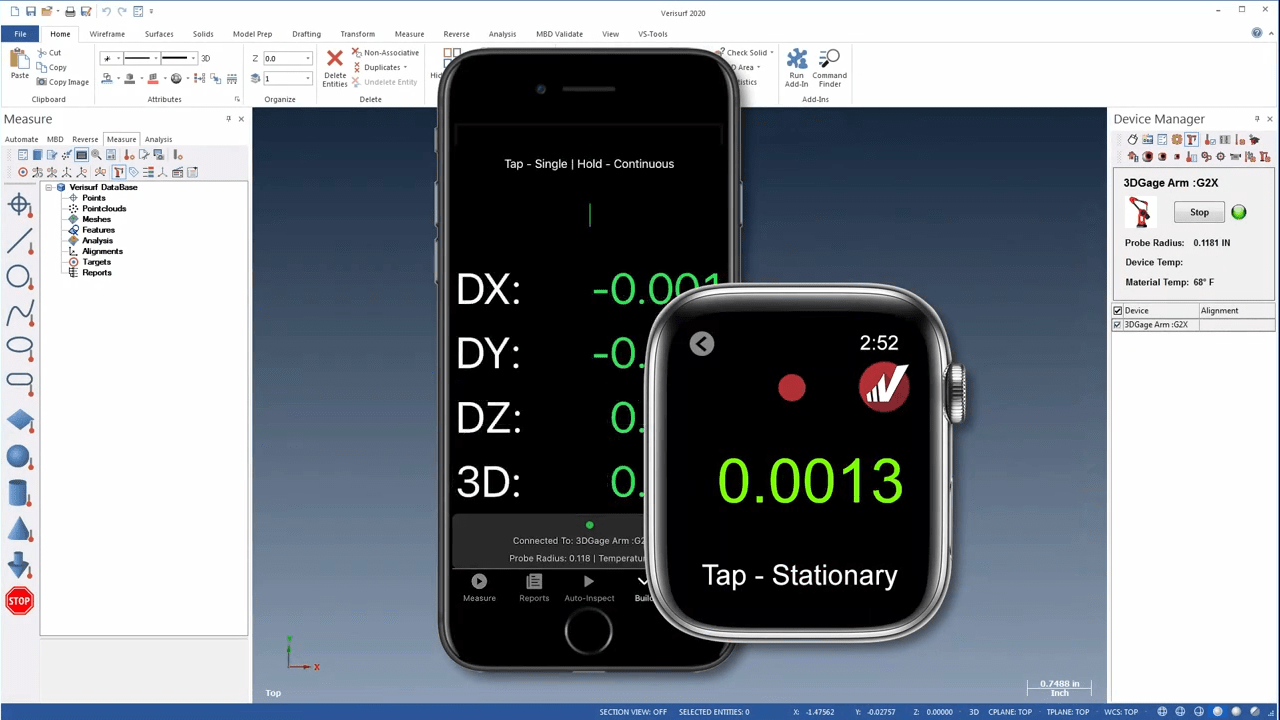

- Mobile Companion & Watch apps

- Auto Center keeps your work on the screen

- Smart Point & Smart Sphere auto-trigger points and scans

- Automated plans and captured views provide highly productive visibility and workflow

NOTE: Certain features supporting the BUILD module are enabled by the CAD and MEASURE modules, required as core modules for BUILD. These modules are part of the Tool Building Suite and the Metrology Enterprise Suite.

The Foundation of Real Time Measurement Suites.

Verisurf CAD and MEASURE modules are the online measurement foundation of Verisurf.

Once you have the basics of measurement you can add specialized modules for your specific Application Suite.