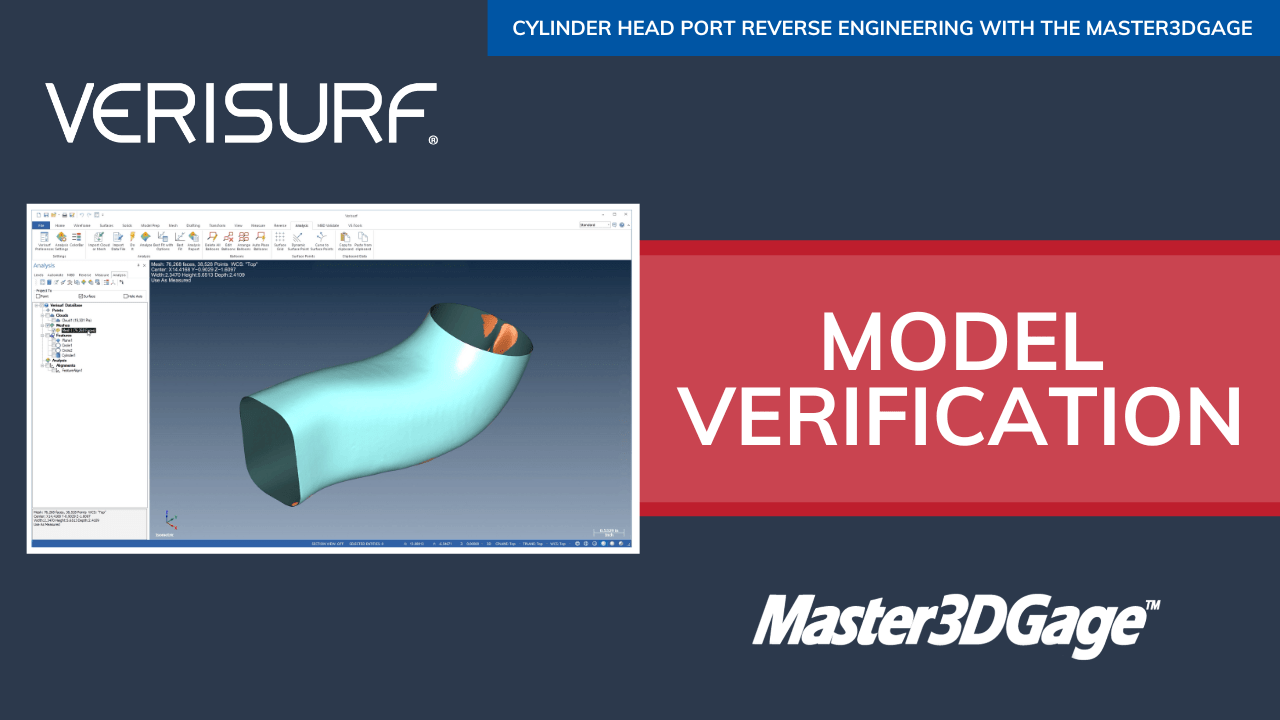

A training video series applying Verisurf software and Master3DGage portable CMM to digitize and scan high-performance engine cylinder heads to reverse engineer and create highly accurate 3D models for manufacturing.

Port Reverse Engineering with the Master3DGage

- Download the software installer

- Install the core software

- Select your measuring device and install the Verisurf Device Interface (VDI) application (if required)

- Navigation and controls of the graphical user interface and measurements tree – practice with sample file

- Ribbon bar, graphics window toolbars, menus and views

- Points, clouds, features and the Operations Managers

- Remove arm, probes and cables from travel and storage case

- Proper setup and mounting of the arm and components

- Secure arm, start the Verisurf device interface

- For first time use, define and align the Port Probe

- Run the user-prompted, quick calibration sequence

- Verify probe calibration results. Device is ready to measure

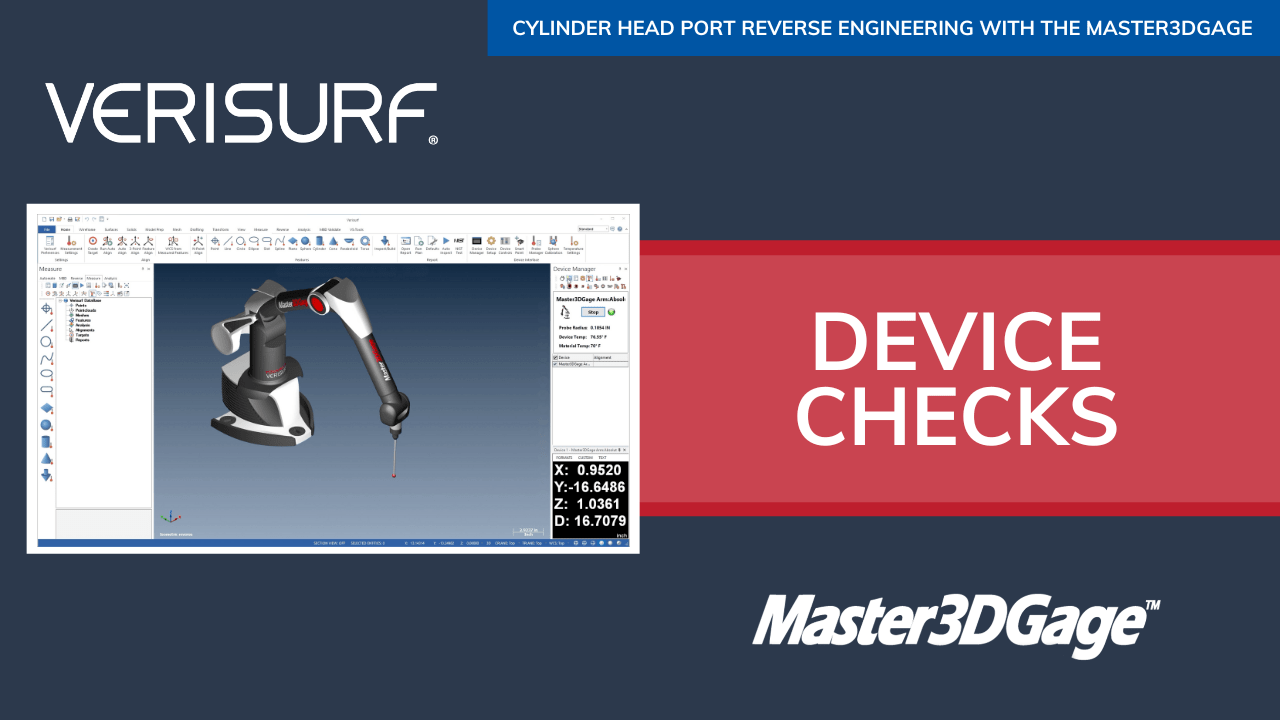

- Quick and easy checks to ensure device and probe accuracy and stability

- Nest probe in a stable location, observe DRO

- Record data on the verification if wanted

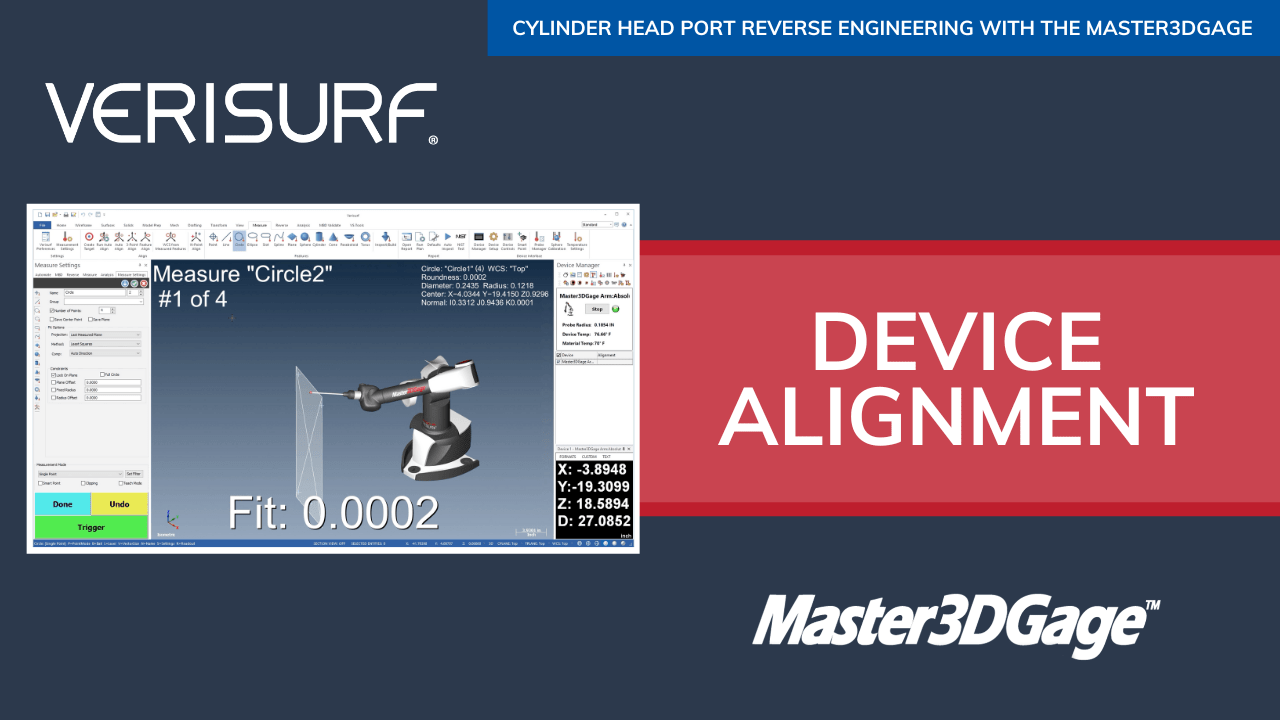

- Simple and fast alignment between cylinder head, Master3DGage, and software coordinate system

- Measured alignment establishes reference system and assures accuracy between ports and features

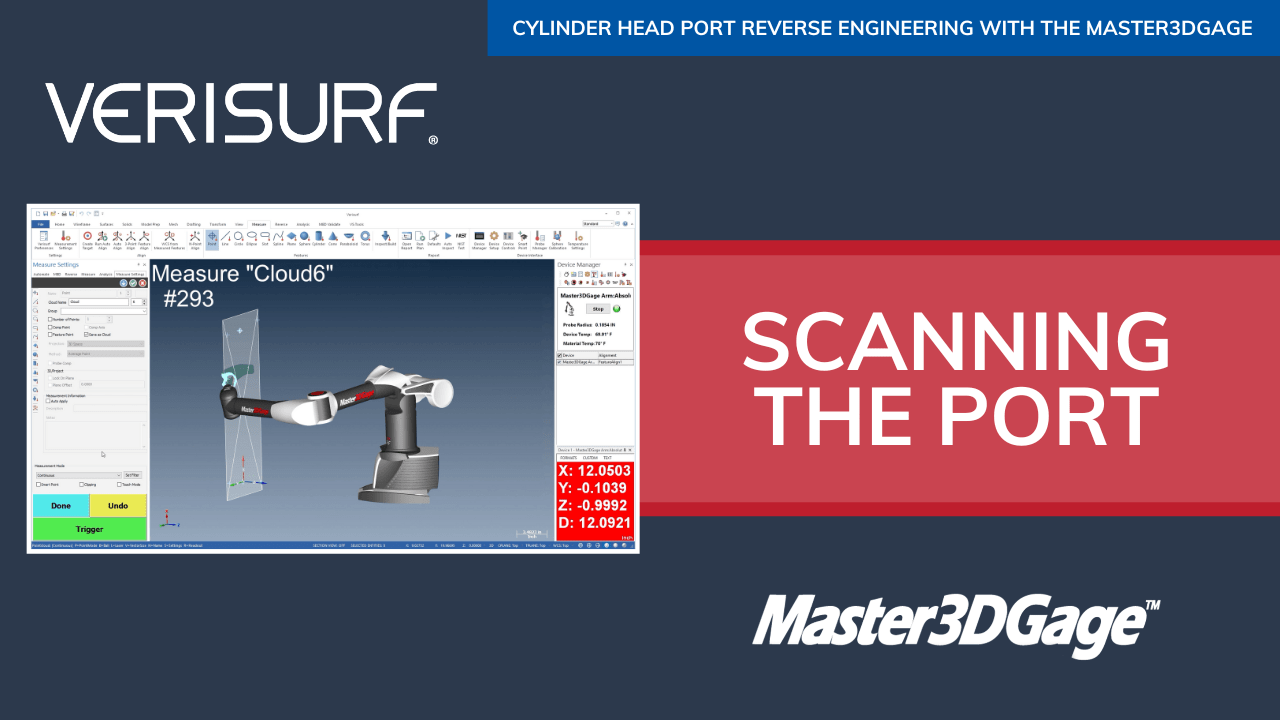

- Using the port probe to “scrub” the inner surfaces

- Control, visualize, re-check, and fill voids to complete the port scan

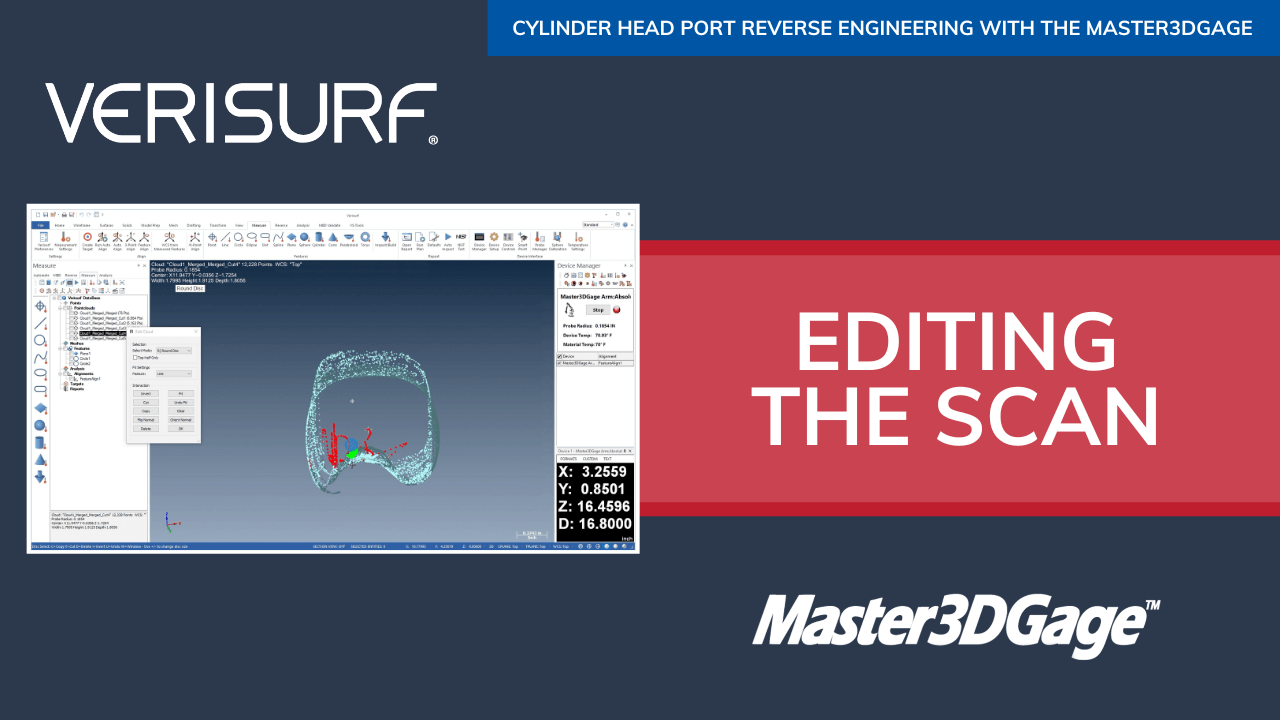

- Clean up the scan by removing outliers and errant points

- Use the intuitive, extensive toolset of cloud edit tools to locate and remove bad points

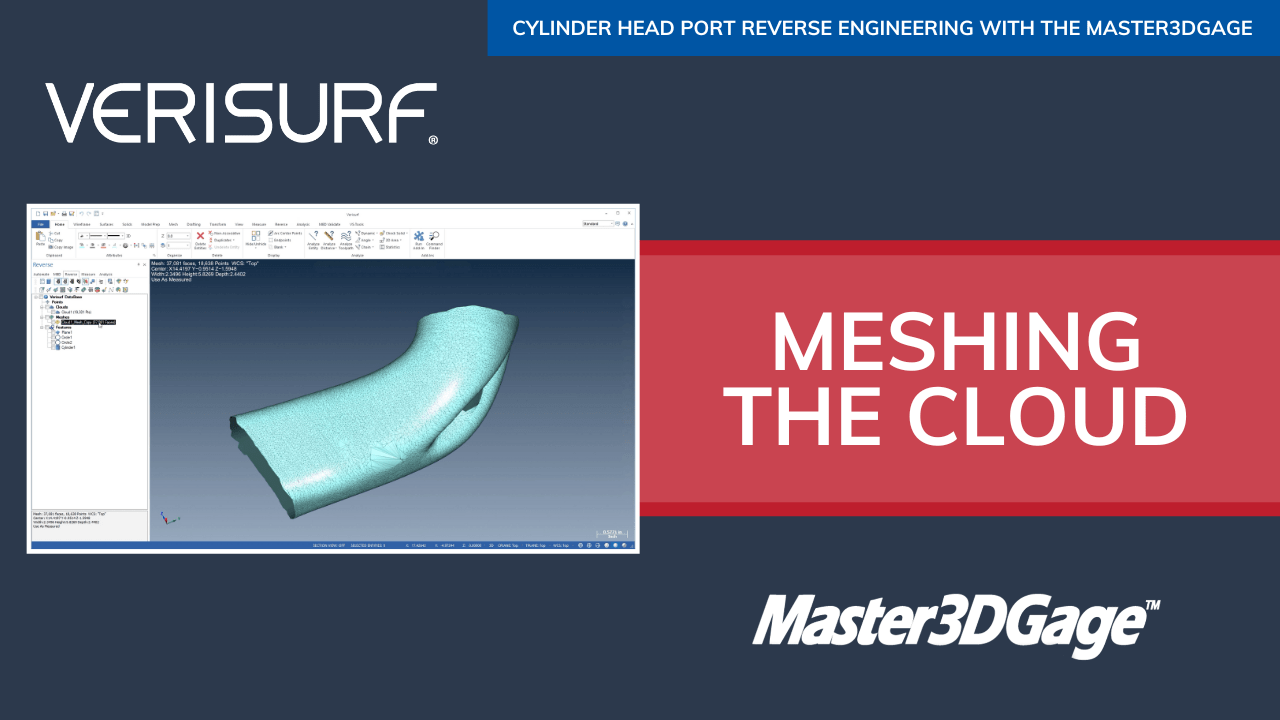

- Create polygonal mesh with just a few clicks

- Offset mesh by the probe radius

- Optimize, refine & trim mesh

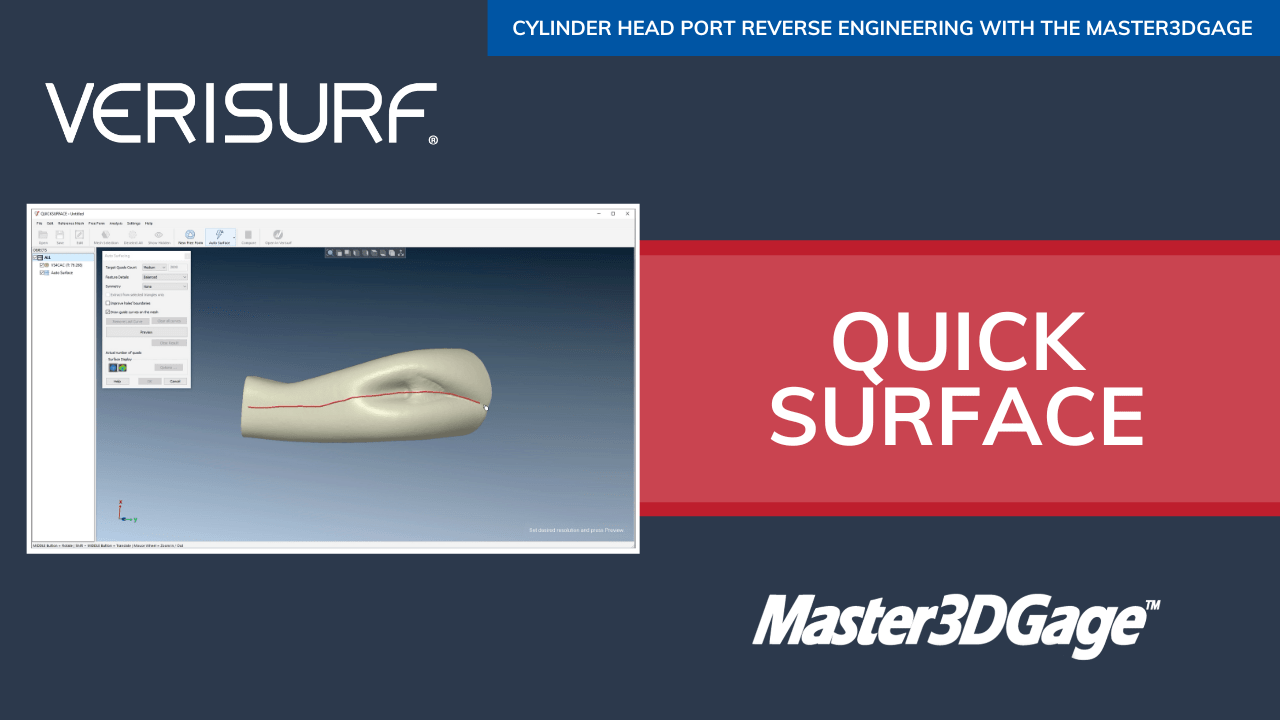

- Create quality surfaces with the Quick Surface option

- Advanced features for refining and making design adjustments to the mesh and resulting surface model

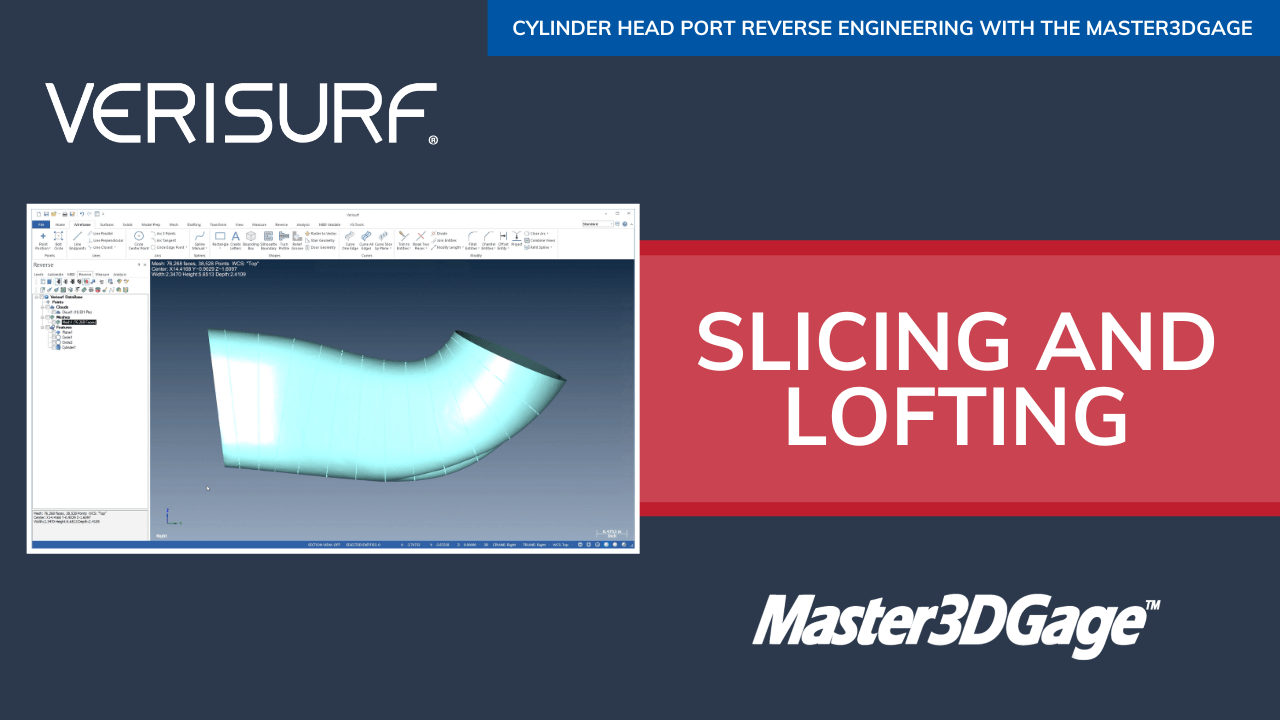

- Alternative surfacing method, mesh slice and loft curves

- Creates a single surface

- Does not require Quick Surface option. Uses more manual CAD functions

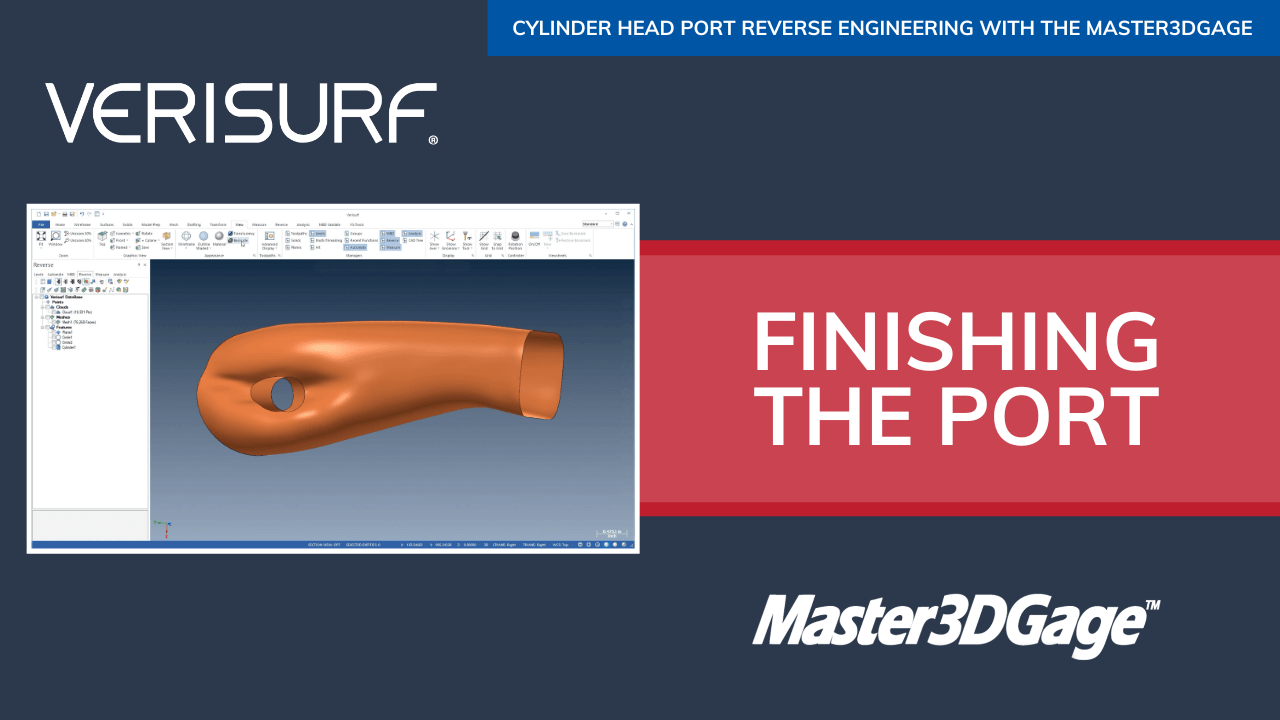

- Final steps, incorporate valve guide, create duplicate ports

- Trim measured valve guide cylinder to port surface

- Copy-transform and mirror the additional 3 ports

- Compare original dataset to the newly created CAD

- Analyze both mesh and point cloud to surfaces

- Use the many tools available to fully understand and refine the process