Alihankinta Show 2025

Alihankinta

September 30-Oct 2, 2025

Tampere Sports & Expo

Tampere, Finland

See Verisurf in the stand of our partner Zenex Hall C, booth C921

The most influential industrial event of the year

The biggest Nordic industrial event will bring together more than 23,000 professionals, the latest innovations, and key topics. Subcontracting enables success – make sure to join us!

Featured Verisurf Technologies in the Booth of Partner Zenex

3D Scanning Inspection & Reverse Engineering

See how Verisurf optimizes handheld 3D scanners for productive and efficient inspection and reverse engineering.Let our pros wow you with automated inspection plans for scanned data. Speed up data acquisition and handling, eliminating much of the tedious and complex work typically associated with scanners and “big data.”

See how Verisurf optimizes handheld 3D scanners for productive and efficient inspection and reverse engineering.Let our pros wow you with automated inspection plans for scanned data. Speed up data acquisition and handling, eliminating much of the tedious and complex work typically associated with scanners and “big data.”

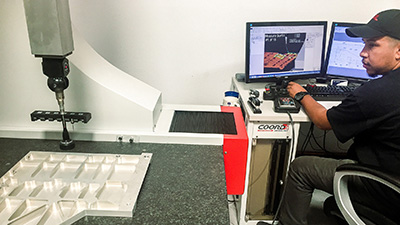

CMM Programming & Inspection

Verisurf CMM programming lets you significantly reduce inspection plan setup from hours to minutes with very little learning curve. Use on any CMM in a revolutionary, click-and-build, graphics rich interface. While allowing users to reduce both programming time and cycle time, the architecture and workflows make it easy for novice operators to become effective even without a lot of experience on CMMs. Ask us about our 5-axis CMM probing exceptional capabilities!

Verisurf CMM programming lets you significantly reduce inspection plan setup from hours to minutes with very little learning curve. Use on any CMM in a revolutionary, click-and-build, graphics rich interface. While allowing users to reduce both programming time and cycle time, the architecture and workflows make it easy for novice operators to become effective even without a lot of experience on CMMs. Ask us about our 5-axis CMM probing exceptional capabilities!

Large Industrial Measurement and Computer-Aided BUILD

Optimize your unique large-volume jobs with modern tracker technology and Verisurf software. Do things with one operator that many have to do with two. Save time and improve your workflow for real-time, computer-aided assembly and tool-building.

Optimize your unique large-volume jobs with modern tracker technology and Verisurf software. Do things with one operator that many have to do with two. Save time and improve your workflow for real-time, computer-aided assembly and tool-building.

Automate the whole process with extremely intuitive, graphical electronic work instructions (program plans) that are a must when you have to work far from the device and computer workstation.

Portable Inspection, Reverse Engineering & 3D Scanning

Verisurf boosts the performance of CMM arms, trackers and scanners to their highest potential, including the scanning operation and post-processing tasks for both reverse engineering and inspection. Automated workflows, automatic feature extraction, full model-based GD&T, and support for all scanning devices are just a few of the many inspection benefits. Reverse engineering includes mesh creation, cleanup, filtering, optimization, registration/alignment, and full CAD-supported parametric modeling.

Verisurf boosts the performance of CMM arms, trackers and scanners to their highest potential, including the scanning operation and post-processing tasks for both reverse engineering and inspection. Automated workflows, automatic feature extraction, full model-based GD&T, and support for all scanning devices are just a few of the many inspection benefits. Reverse engineering includes mesh creation, cleanup, filtering, optimization, registration/alignment, and full CAD-supported parametric modeling.

Industries and Applications:

- Aerospace

- Automotive

- Energy

- Industrial

- Medical

- Automation

- 3D printing and additive manufacturing

composites, plastics, metals, forgings, castings, CNC machined and 3D printed parts measurement