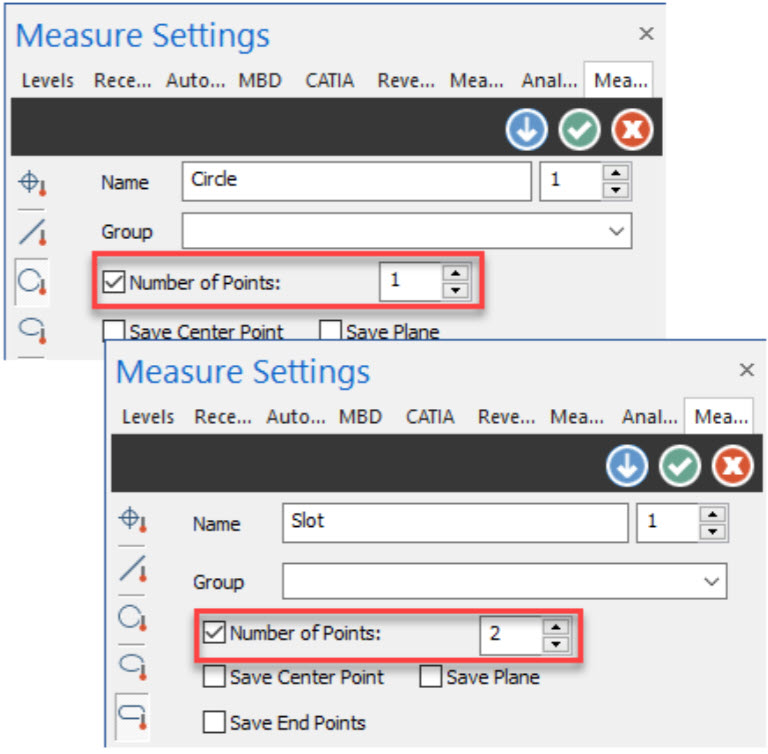

Tech Tip – Measuring Single Point

Circles and 2-Point Slots

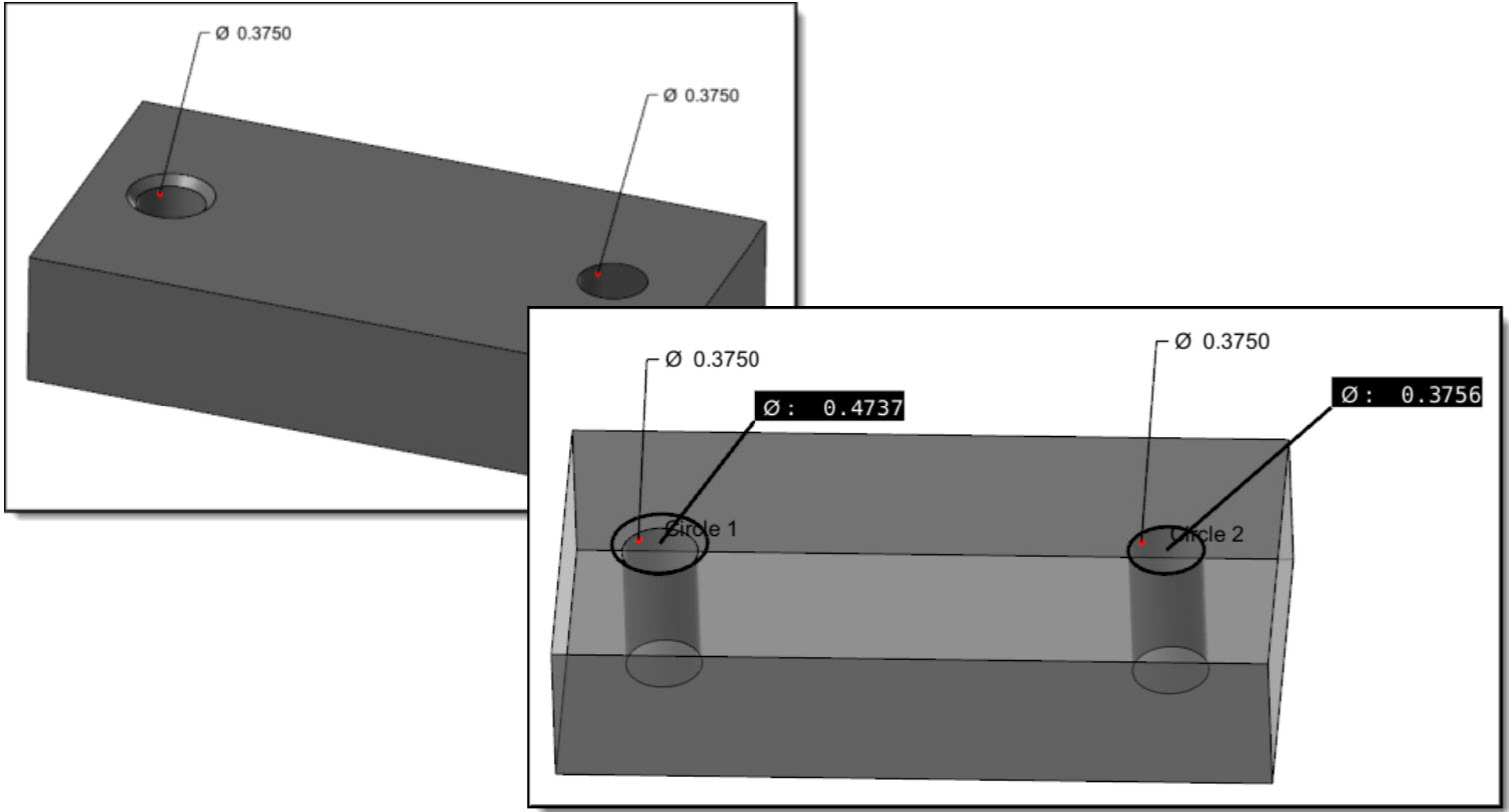

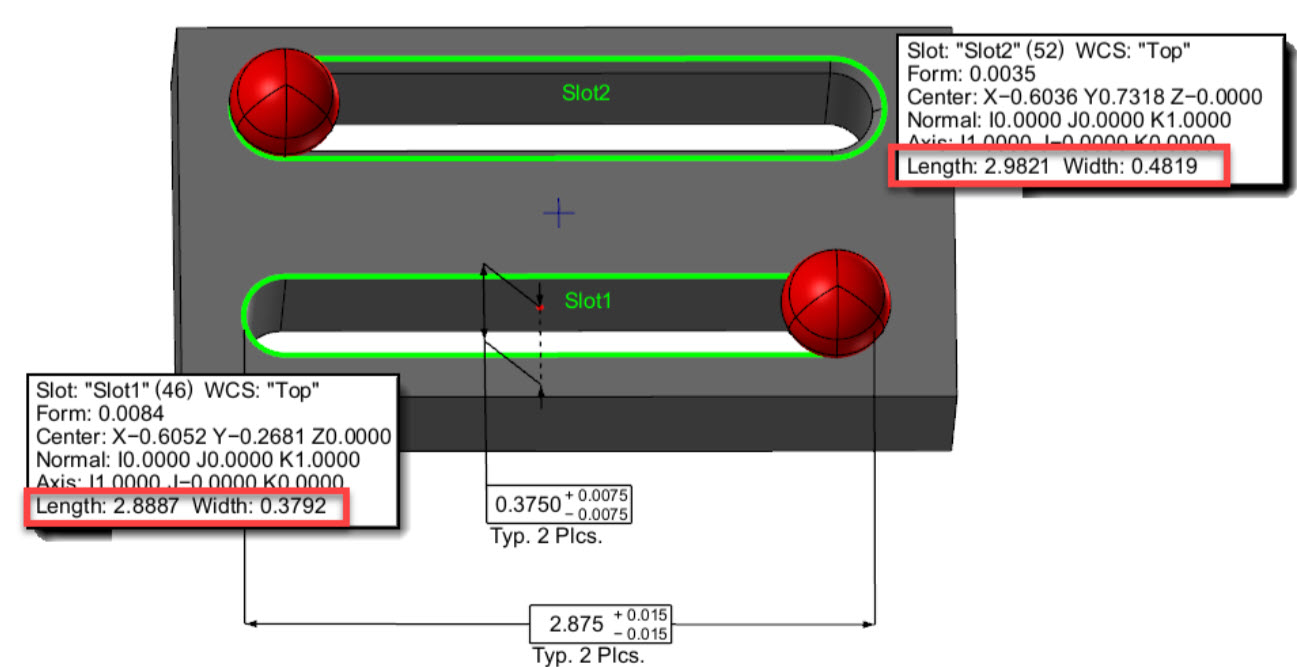

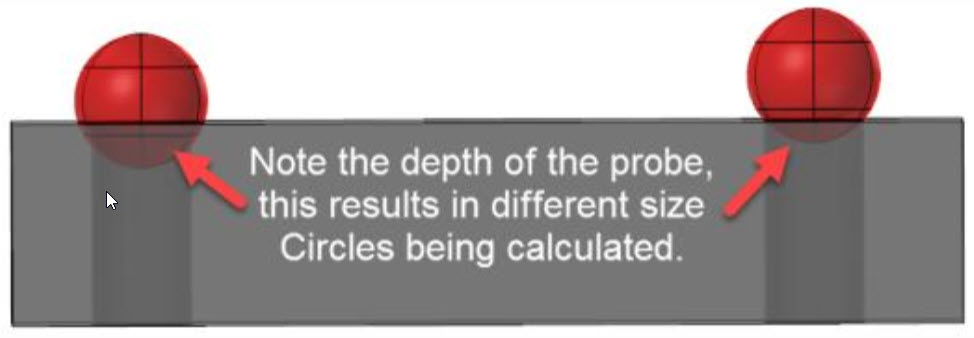

The single point circle and 2-point slot method are calculated based on the measured Plane and the diameter of the Probe used for measurement. Verisurf reads the Probe diameter with each measurement so it is easy to understand that the calculation for these features is the intersection of a Sphere (the probe) and the measured Plane. At this intersection, the Diameter of a Circle is calculated or the length and width of a slot are calculated. Since the calculation is done at the intersection of the Probe and the Plane it is critical that the edge of the hole or slot is not damaged or beveled in any way. The quality of the edge can impact the size and location of the Hole or Slot. However, it is possible to measure the location of a Hole with a uniform countersink accurately if necessary.

The two illustrations shown right – a Hole with a good edge and one with a bad edge.

The following examples demonstrate how holes and slots of the same size give different results due to countersinking or chamfering of the hole or slot.

Verisurf Software, Inc.

Verisurf Software, Inc. is an advanced three-dimensional measurement solutions company committed to delivering advanced computer-aided inspection and reverse engineering solutions. Verisurf software helps manufacturers of all sizes and industries produce higher quality products in less time and at a lower cost with automated, Model-Based Inspection processes. For more information, visit the Verisurf website at https://verisurf.com.