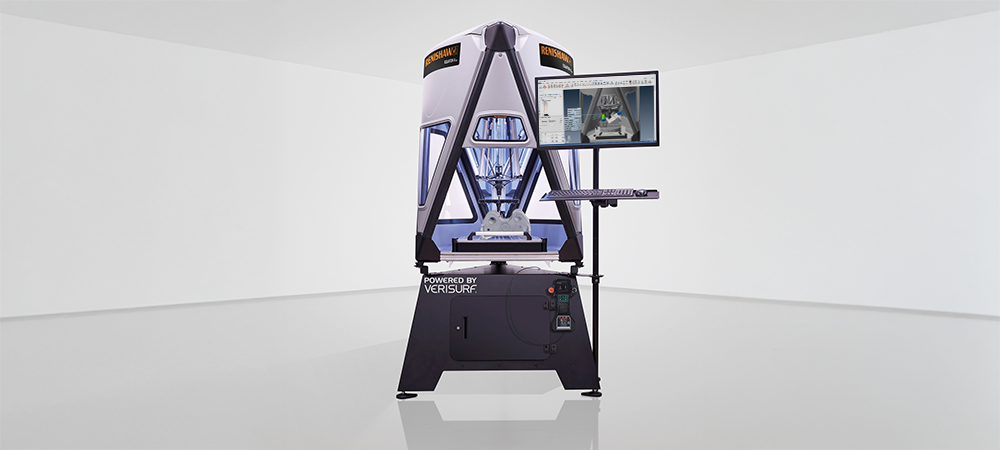

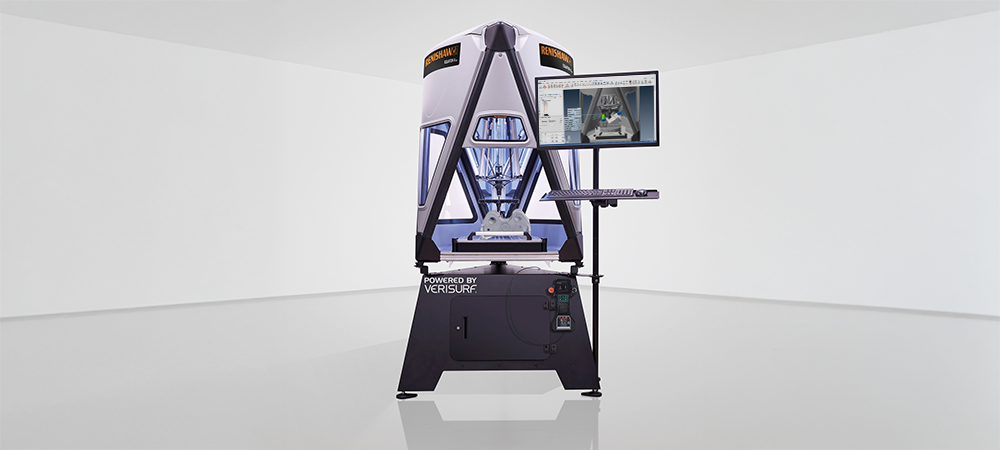

Verisurf Announces Support for New Renishaw Equator-X

Combined with Verisurf software for the highest productivity and ease of use available. Full press release:

Scott KnocheJune 25, 2025