KEY BENEFITS

Verisurf VALIDATE is for aerospace part suppliers with DPD/MBD process requirements. It provides precise CAD model translation validation by comparing the authority CAD model to the translated CAD model, enabling manufacturers to quickly identify any translation error. Verisurf VALIDATE helps reduce scrap and rework from bad CAD translations and complies with Boeing D6-51991 “Quality Assurance Standard for Digital Product Definition”.

KUBOTEK KOSMOS VALIDATE Standard

Includes the following functions.

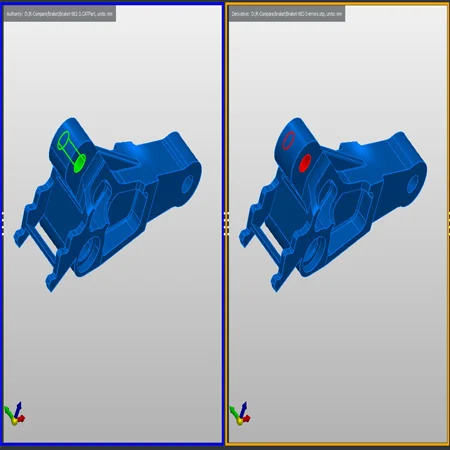

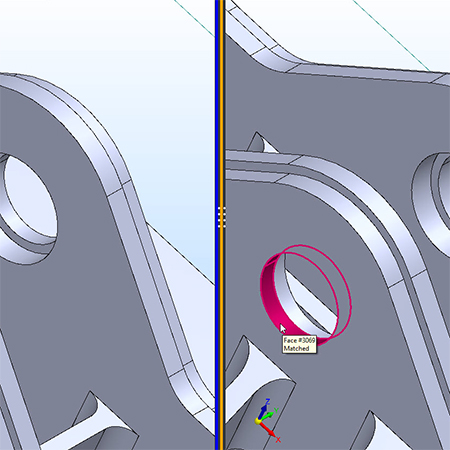

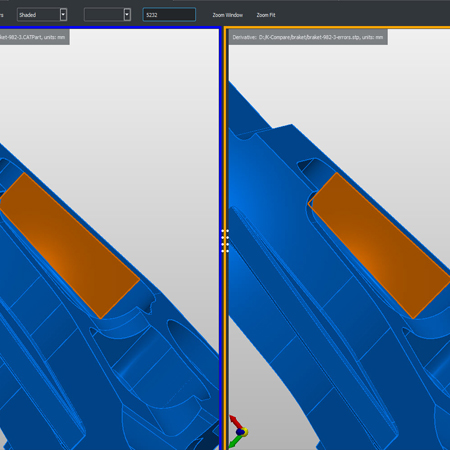

Advanced Geometric Comparison

Face-to-face geometric pattern matching analyzes the whole part definition within the user controlled tolerance. This strategy reliably finds the differences across all precise CAD models without the common failures and false positives of the Boolean approach, or missed areas inherent with the sampling of points approach.

Boeing D6-51991 Compliance

Boeings quality system requirement for Aerospace suppliers with sections that require translated CAD data to be validated for quality system compliance.

Distance Measurements

Measure the distance between entities, points, and positions and angles between two edges or faces, or 4 positions.

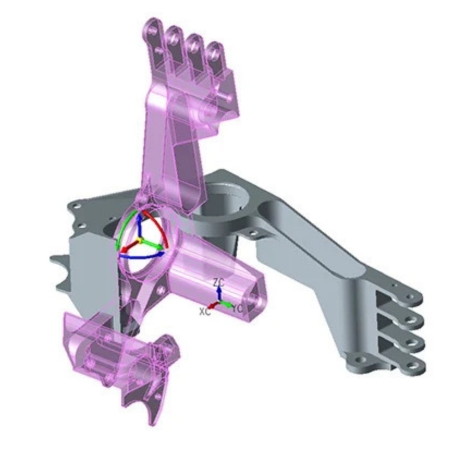

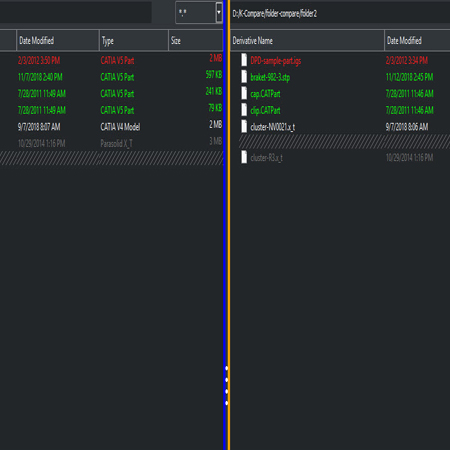

Assembly

Comparison

A special mode for two sets of hierarchical CAD assembly files scans file names and headers and lists side-by-side results. Users can optionally geometrically compare a selected set of parts or launch processes to compare all parts. Quick side-by-side 3D graphical viewing is available to see differences in impacted parts.

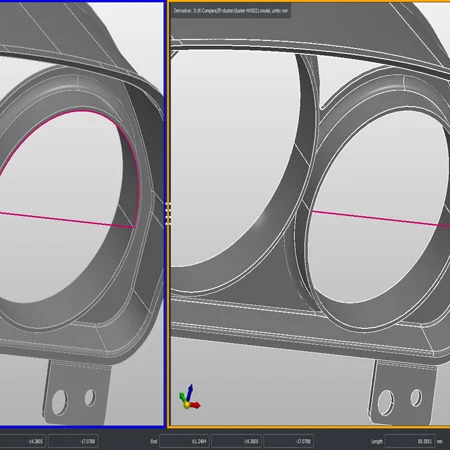

Selective

Comparison

When the authority or derivative files have extra data that is inconsequential to validation, a selective compare can be accomplished by choosing the data from each file for comparison.

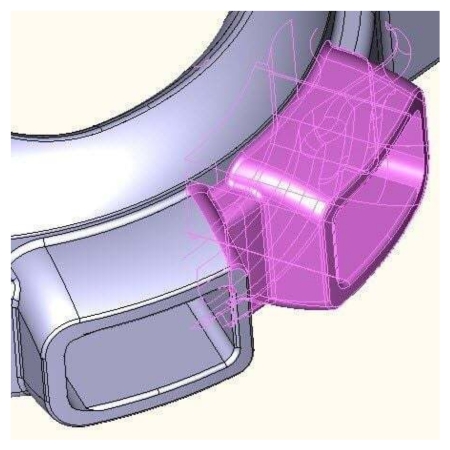

Re-Orientation of Derivative

When the derivative data is in a different orientation than the authority data (typically for manufacturing setups), the derivative can be automatically or manually oriented to match the authority data before comparison.

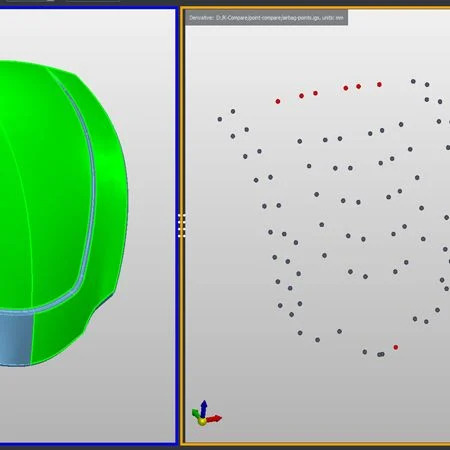

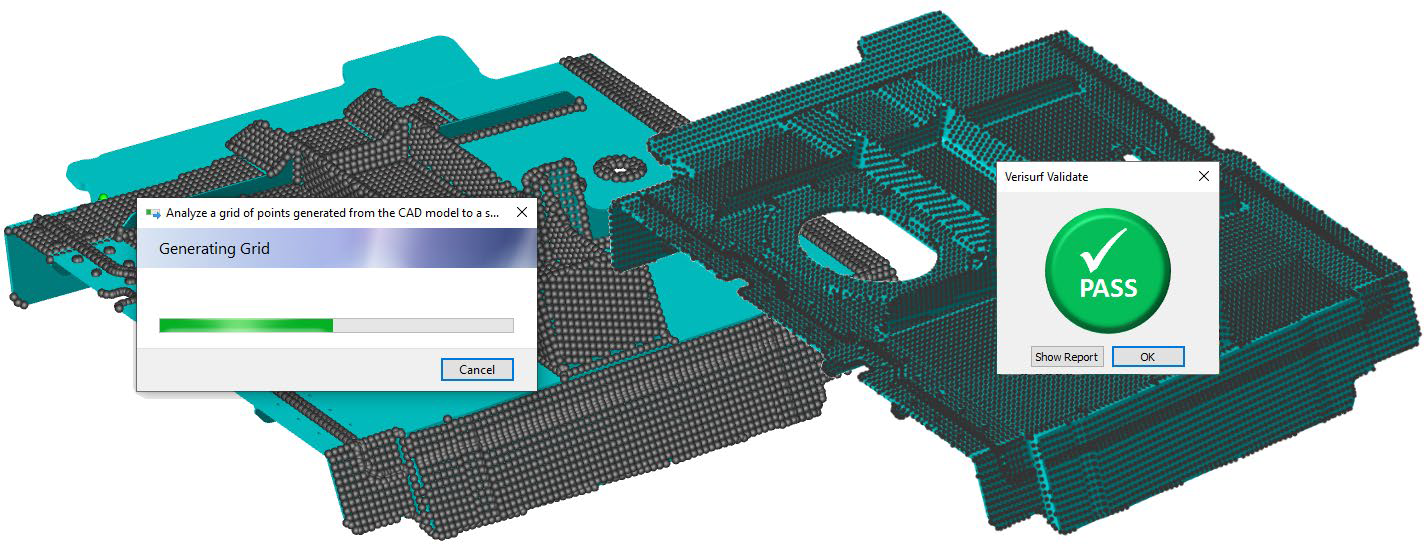

Non-Solid Derivative Files

When the software that is receiving a solid model of the design data can not output a solid model (some metrology software) the translation of the authority data is validated by outputting a point cloud that represents the measured points on the data. This point data is compared to the authority solid and surface data to perform the validation.

A similar approach is used to compare mesh data in STL derivative files to the precise authority data set (Premium level only).

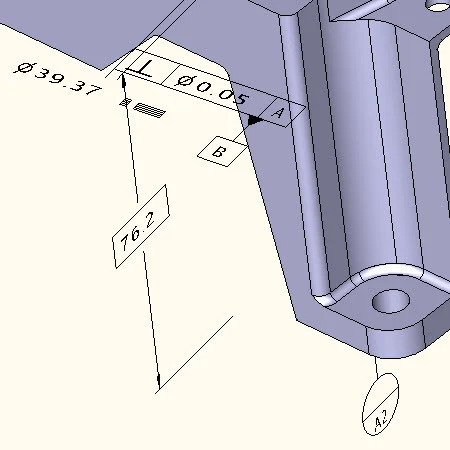

PMI

Annotations

Compare semantic differences in Product Manufacturing Information (PMI) including 3D geometric tolerances from these formats:

Dassault CATIA

PTC Creo

Siemens NX

Dassault SolidWorks

STEP AP 242

Optional Network

License

Benefits of network floating licenses:

- Access software from multiple devices and locations.

- Unlimited number of users.

- More flexible and dynamic software usage.

- Shared software can result in significant savings.

Example of two concurrent users of network floating licenses managed from network license server.

STEP

STEP, STP, STPZ

IGES

IGES, IGS

Dassault CATIA V5

CATPart, CATProduct

SolidWorks

SLDPRT, SLDASM

Siemens NX

PRT

Siemens JT

JT

PTC Creo

PRT, ASM

KUBOTEK KOSMOS VALIDATE Premium

Including all the functions of Standard plus the following.

Batch Comparison

Sets of authority and derivative files can be batch processed through the user interface or executed from the command line.

Error Dispositioning

Inconsequential errors found as a result of compare can be quickly dispositioned with a short text explanation and documented in the output quality document.

Validation Traceability

Quality documents include built-in features that provide traceability back to the original validation to meet audit requirements.

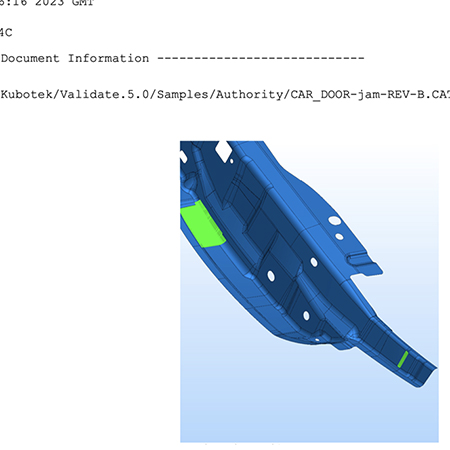

Image

Captures

Images of differences can be automatically included in the output quality document.

Certified Quality Document (Text)

Comparison results recorded as certified, tamper-proof ASCII text documents customized with your company name.

Certified Quality Document (PDF)

Comparison results recorded as certified, tamper-proof PDF documents customized with your company name.

Sandvik Mastercam

MCX

Dassault CATIA V4

MOD

Dassault CATIA V6

3DXML

Autodesk Inventor

IPT, IAM

Kubotek KeyCreator

CKD

Siemens Solid Edge

PAR, ASM, PSM

Siemens

Parasolid

X_T, X_B

Dassault (Spatial Corp.) ACIS

SAT, SAB

AutoDesk

DXF & DWG

DWG, DXF

CAD Translation Validation for Manufacturing

Complete Aerospace Inspection With CAD Validation Package