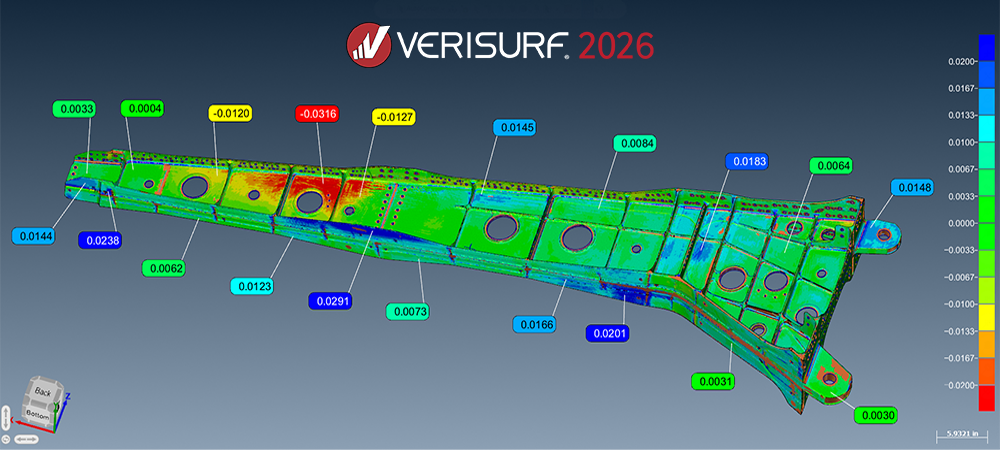

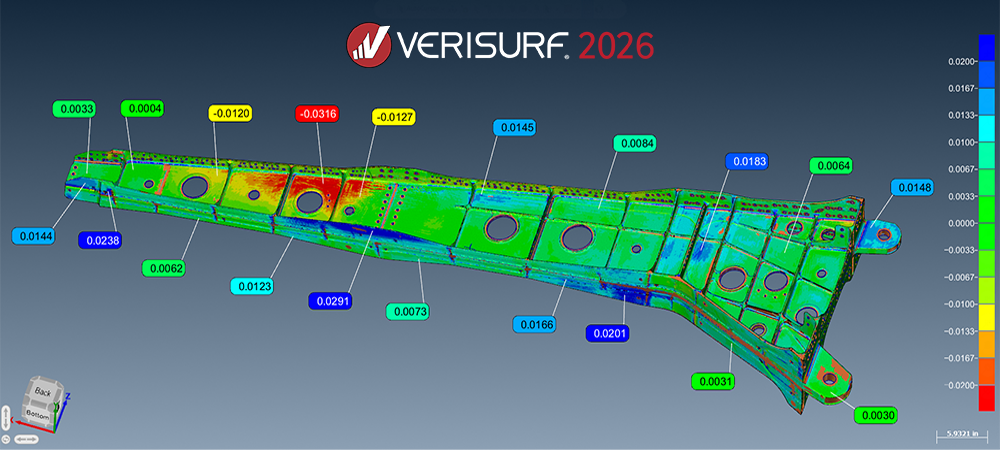

New Verisurf 2026 Measurement and Inspection Software

New features and workflow improvements help manufacturers reduce costs, save time, and enhance process control across all stages of digital manufacturing:

Scott KnocheSeptember 4, 2025