Somebody Always Has to Go First: Grand Traverse Tool Becomes First Haas CMM Customer with Verisurf Software Integration

By David Olson, Verisurf Software Inc.

Grand Traverse Tool is the very first customer of the new Haas CMM solution, powered by Verisurf inspection and measurement software.

Traverse City, Michigan, has a long history of “firsts” in American manufacturing. In the 1940s, it was here that the first NC machine tool (Numerically Controlled) was developed to produce complex helicopter blades – an innovation that would forever change the aerospace industry. Decades later, another first emerged from this same region when Grand Traverse Tool, a precision machining company founded in 1995, became the first customer in the world to purchase and implement a Haas CMM, powered by Verisurf software.

For Jeff Gothrup, President and CEO of Grand Traverse Tool, that pioneering move wasn’t surprising. “Somebody always has to go first,” he said. “We’ve always tried to balance tradition with innovation. Our customers expect precision, and when Haas introduced their first CMM at IMTS 2024, we saw an opportunity to take another big step forward.”

From Mold Making to Mission-Critical Parts

Grand Traverse Tool began in November 1995 as a high-precision mold and die shop. Over the years, the company expanded into general machining, eventually becoming a trusted supplier for industries that demand the highest quality and tightest tolerances. Today, the shop produces components for medical devices, energy systems (including those for gas and oil), aerospace and drone applications, maritime systems, and monitoring systems.

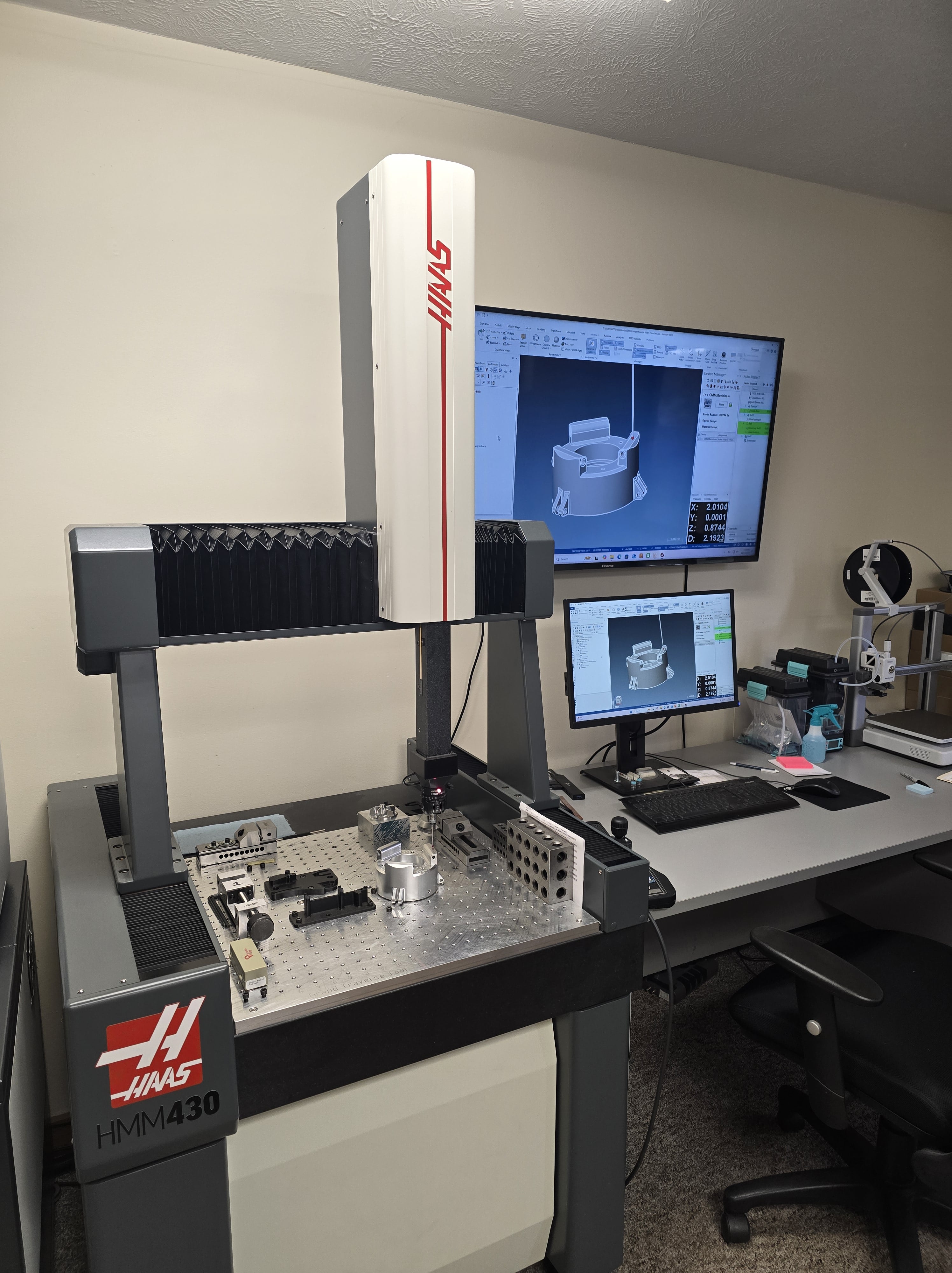

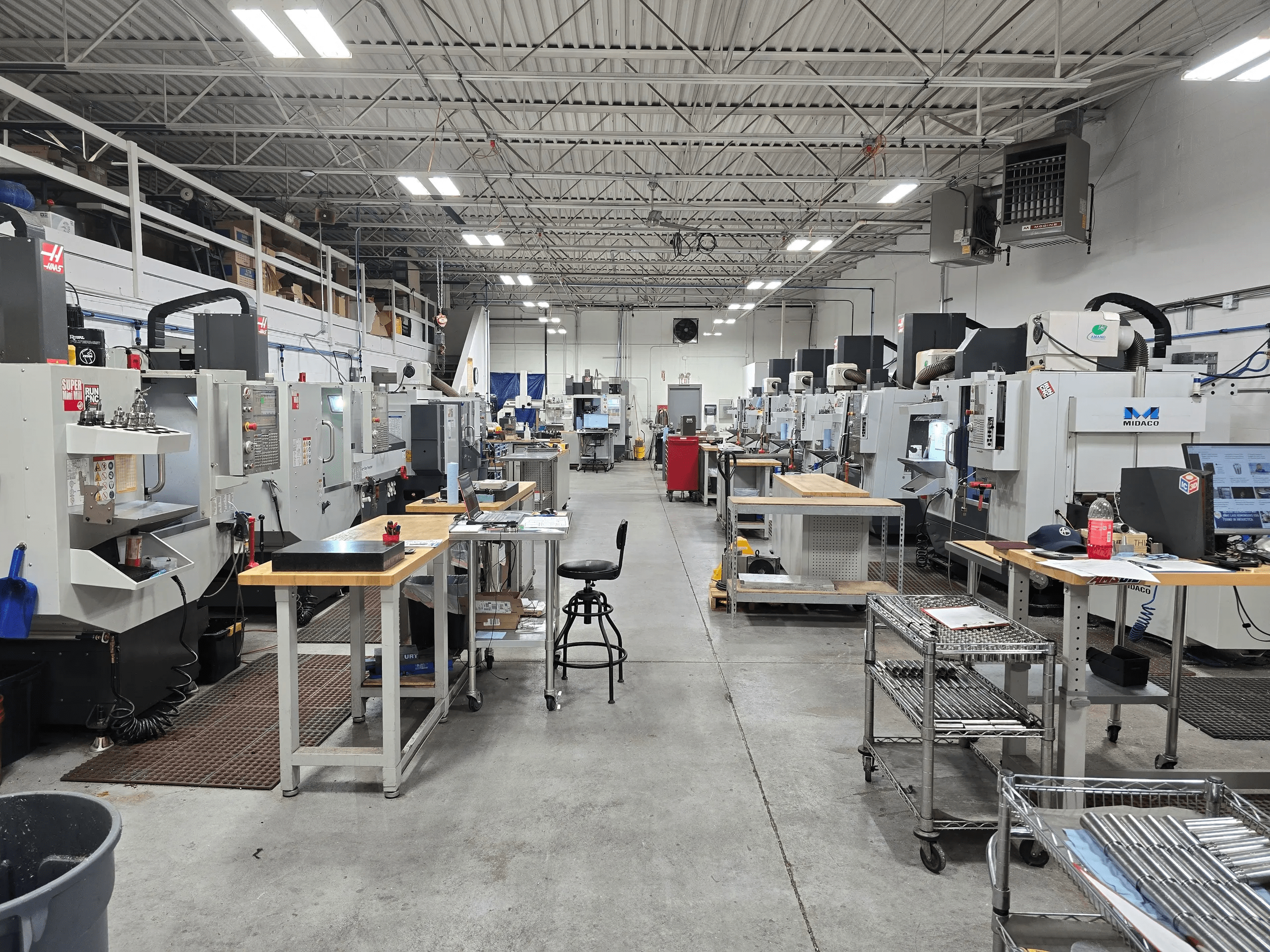

Grand Traverse Tool is a clean, well-organized shop dedicated primarily to Haas milling and turning solutions.

With just seven employees and ten Haas vertical mills, eight of which are equipped with on-machine probing, Grand Traverse Tool runs lean yet sophisticated. The shop uses Fusion 360 for CAD/CAM programming, supported by Haas probing systems for automated part and tool setup, monitoring tool wear and breakage, and verifying correct part loading on the CNC machines. New equipment, including a Haas 5-axis UMC VMC and a Tornos Swiss Lathe mill, is being installed to further expand capabilities.

With only seven employees, Grand Travers Tool is able to provide extensive design consulting and engineering services and effectively produce more throughput than shops that are more than twice their size.

The company has developed a reputation not only for its machining expertise but also for its engineering and consulting services. Customers frequently come to Grand Traverse Tool for design-for-manufacturing support, problem-solving, and process improvements. Gothrup explained: “Our customers know we care about every project, every part. We’re proactive in finding ways to improve manufacturability and are reactive when issues arise. That combination has built long-term trust.”

This consultative approach has enabled Grand Traverse Tool to enter unique markets. One early customer was Pace Pal, manufacturer of an underwater training clock for competitive swimmers used at the Olympic and high school levels. The company also collaborated with a start-up to help design and build drones for internal inspection of large tanks used to store water, petroleum products, and other materials. The specialized drones were also suitable for other confined, low-light/no-light applications such as search and rescue operations. Each new venture reinforced Grand Traverse Tool’s ability to tackle complex challenges and to adapt to emerging industries.

The Challenge: Scaling Quality Control

As Grand Traverse Tool has moved deeper into the medical, aerospace, and energy markets, quality verification requirements have become increasingly demanding. Many parts now require complete Production Part Approval Process (PPAP) documentation. For example, every new medical part requires inspection of the first 30 pieces, followed by three pieces per thousand during production, as well as critical tolerance checks on nearly 5% of all output.

“We are constantly looking for better ways to maintain close tolerances while increasing machining efficiency, it’s just the nature of the business,” Gothrup said. “Our primary goal in adopting a CMM was the ability to quickly set up and inspect individual parts and mixed batches in various volumes.”

This drove Gothrup’s decision to visit IMTS 2024 in search of a dedicated coordinate measuring machine. Given the shop’s 20-year reliance on Haas vertical mills, Haas was already on his short list. What he didn’t expect was that Haas would debut its first stand-alone CMM at the show. The timing was perfect.

“It was inevitable that we became the first Haas CMM customer,” Gothrup said with a smile. “The relationship was already there, and Haas was finally bringing metrology into their ecosystem.”

The First Haas CMM Installation

Haas sent three technicians to Traverse City to install the very first Haas CMM sold worldwide. While the machine itself met expectations, the software presented an immediate challenge. The OEM software relied heavily on G-code editing and lacked seamless integration with CAD models. For a shop that lives in the world of model-based manufacturing, this was a significant limitation.

“We loved everything about the CMM, but not the software,” Gothrup admitted. “We needed something that could relate measurement data directly back to the 3D CAD model. That’s when we were introduced to Verisurf.”

Verisurf software is built on the Mastercam platform. The software supports all CAD files, and digital sensor devices, including CMM, portable arms, scanners, trackers and more. Verisurf is one of the most versatile and powerful and compatible inspection and measurement platforms available, today.

Through a connection in southern Michigan, Gothrup discovered Verisurf, a powerful model-based metrology platform. After testing it, he quickly realized it was the missing piece. “I liked Verisurf CMM Manager immediately. Verisurf delivered on everything we needed to maximize the value of our Haas CMM – we use it every day.”

Verisurf in Action

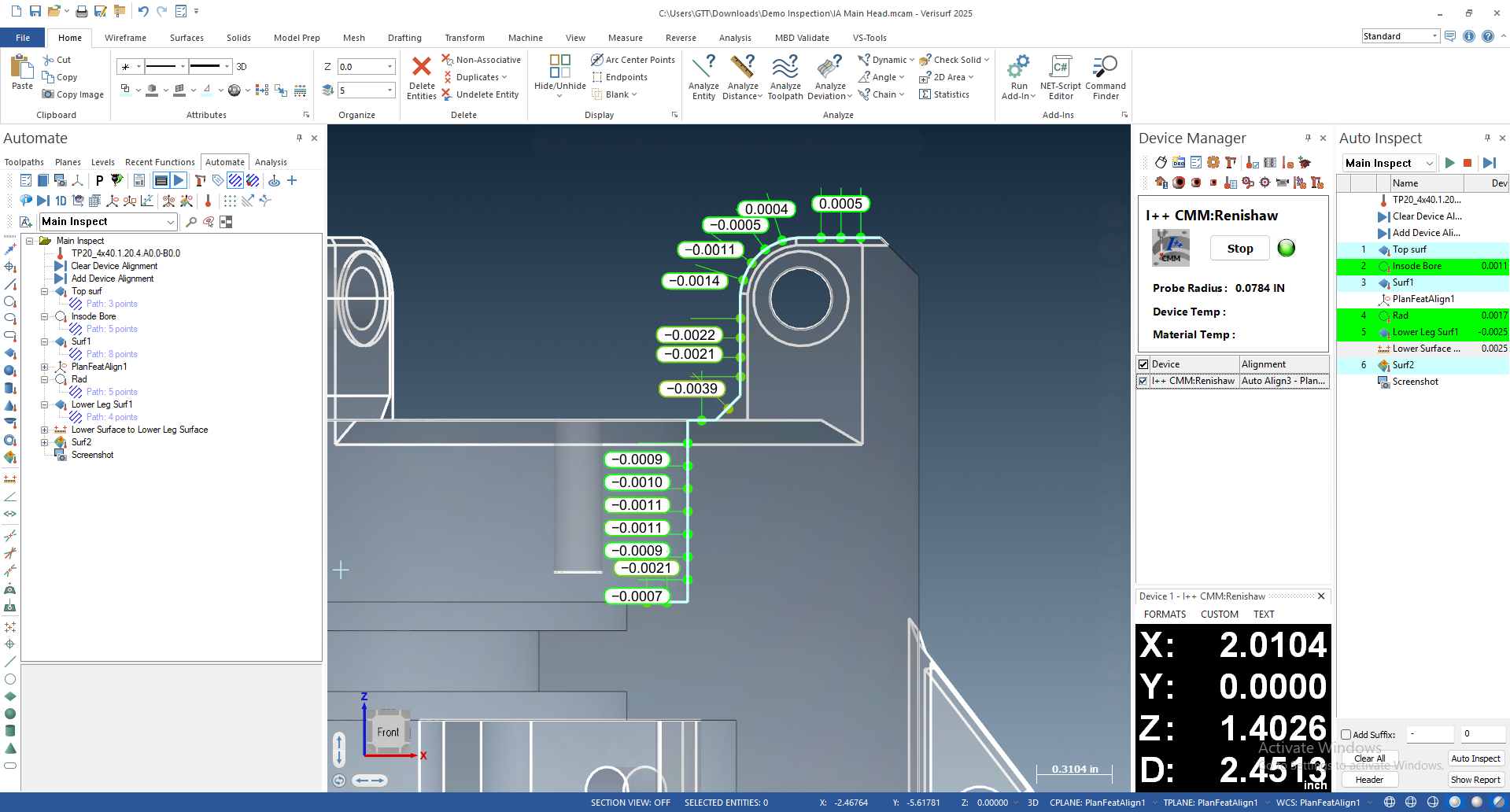

By pairing the Haas CMM with Verisurf software, Grand Traverse Tool gained a complete model-based inspection solution. Verisurf enables machinists to import a 3D CAD model as the “virtual golden part” and then automatically drive the CMM to align and measure the physical part.

When re-running jobs, multiple parts and fixtures can remain in place on the CMM table simultaneously. This allows each machine operator to quickly load a part, call up the Verisurf inspection routine, and complete in-progress feature verifications.

For recurring jobs, Grand Traverse Tool takes the process even further. The team designs and 3D prints custom fixtures for each family of parts. When a new run begins, the operator loads the first finished part into its dedicated fixture, places it on the CMM, calls up the inspection plan in Verisurf, hits “play,” and lets the software handle alignment, probing, and reporting.

The impact on production efficiency has been significant. Machinists now cut the first part of a run, bring it to the CMM, and within minutes have any deviations from nominal tied directly to the CAD model. Any out-of-spec conditions are flagged immediately, allowing the machinist to make necessary adjustments. Typically, by the first or second part, the run is dialed in and stable. Finished part inspection and reporting is then completed as required by customer specifications.

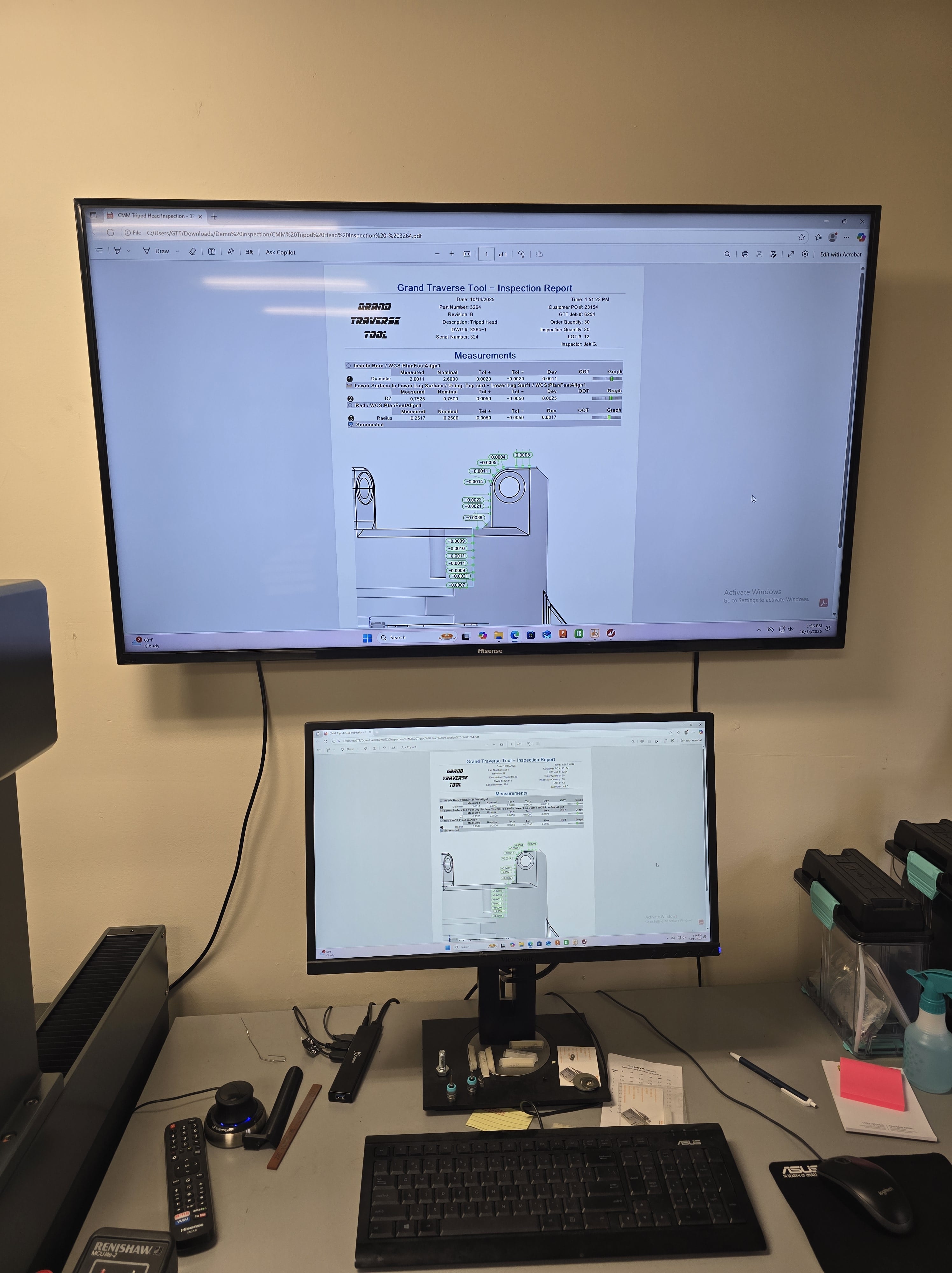

Verisurf software presents real-time deviation of parts compared to the CAD nominal. Easy-to-read reports can also be generated in a variety of business presentation formats.

“Verisurf provides a direct feedback loop between inspection and machining,” Gothrup explained. “It allows our machinists to set up and validate parts quickly and accurately, which saves time and reduces scrap. Verisurf software has made our Haas CMM a true asset.”

A Culture of Problem Solving

Choosing to be the first Haas CMM customer was more than a business decision; it reflected the culture of Grand Traverse Tool. From the beginning, Gothrup built his company around engineering support and problem-solving. Customers don’t just send drawings for quotes; they often seek design consultation and manufacturability improvements.

That collaborative spirit has attracted customers across industries. Whether it’s a swimming clock, a drone for hazardous inspections, or a medical device requiring rigorous PPAP documentation, Grand Traverse Tool applies the same care and engineering rigor.

“Our customers know we’re in this with them,” Gothrup said. “We’ve built a reputation for finding solutions, and the Haas CMM with Verisurf is an extension of that approach.”

Partnership and Support

Behind the technology, strong relationships remain key. Gothrup credits Haas Factory Outlet–Grand Rapids, specifically service representative Jeramy and sales contact Rob, for their support throughout the process. “They’ve been great to work with,” he said.

He also notes the dedication of Verisurf’s team, who invested a significant amount of time during the implementation. “Verisurf spent the time many others wouldn’t,” Gothrup emphasized. “That made a big difference; our inspection and reporting application would not be as good as it is without them.”

Looking Ahead

Grand Traverse Tool continues to invest in its future. Along with the Haas CMM and Verisurf software, the shop is expanding its machining capabilities with the addition of a Haas 5-axis UNC VMC and a Tornos Swiss Lathe mill. These machines, combined with the closed-loop inspection process powered by Verisurf, will enable the company to tackle even more complex parts for aerospace, medical, and energy markets.

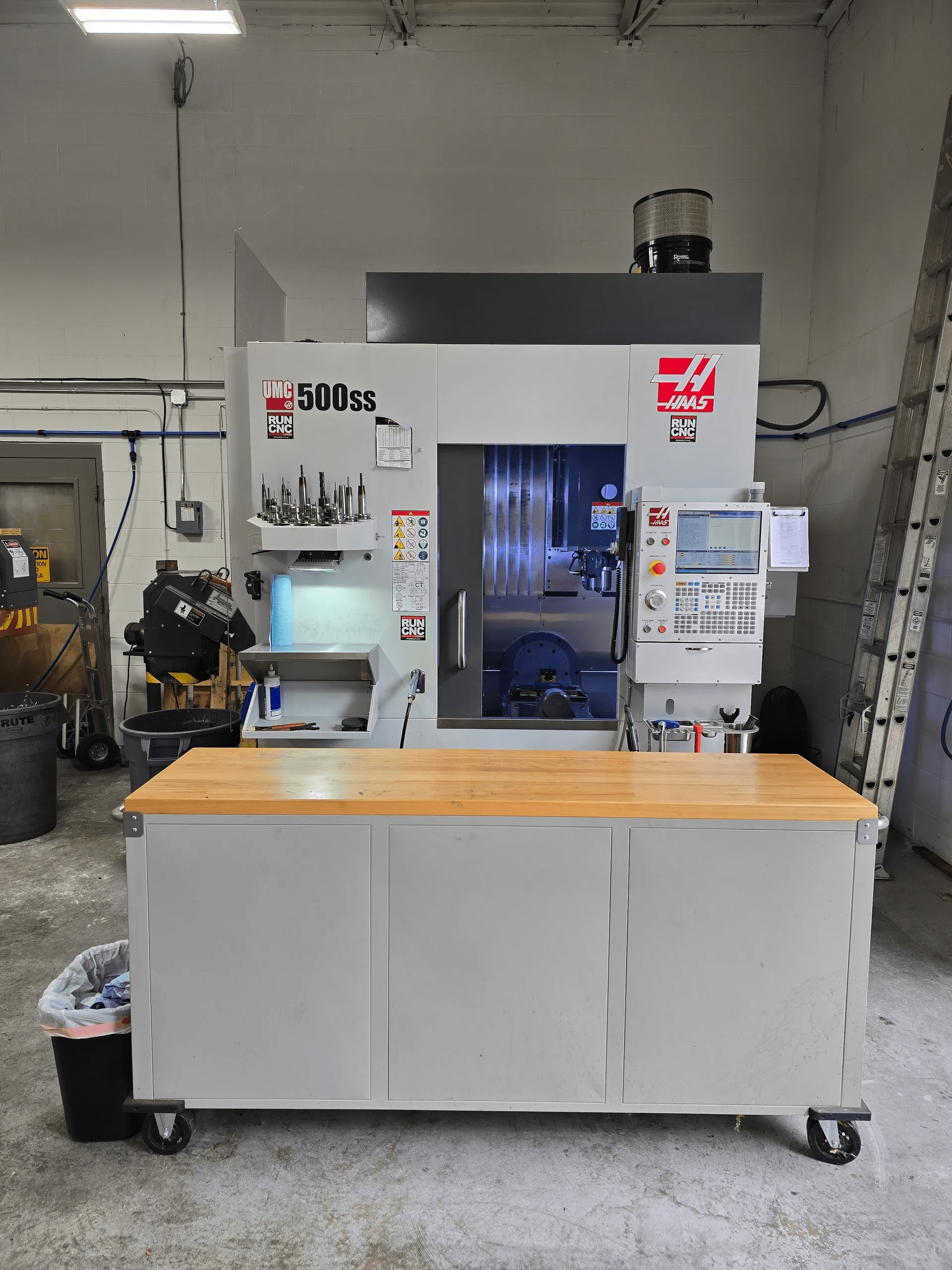

Grand Traverse Tool continues to invest in productivity enhancing solutions, like the Haas UMC-500SS Series, 5-axis VMC. These next generation machines offer all the benefits of 5-axis milling, plus the ability to perform on-machine probing of finished parts, using Verisurf software - further closing the loop in digital manufacturing.

But through all the advancements, the pioneering spirit remains unchanged. Just as Traverse City was home to the first CNC machine 80 years ago, it’s now home to the first Haas CMM installation. And Grand Traverse Tool is carrying that legacy forward.

“Somebody always has to go first,” Gothrup repeated. “We’re proud to be that somebody, especially when it means delivering better results for our customers.”

About Grand Traverse Tool

Founded: 1995

Location: Traverse City, Michigan

Employees: 7

Industries Served: Medical, aerospace, drones, energy, maritime, industrial monitoring systems

Core Equipment:

- 8 Haas Vertical Mills

- 3 Haas 5-Axis UMC2 Haas lathes

- Tornos Swiss Lathe

- 1 Haas HMM430 CMM with Verisurf Measurement and Inspection Software

- Fusion 360 CAD/CAM Software

For more information, visit https://grandtraversetool.com/ or https://www.verisurf.com/