Catamount Machine Works: Commitment to Rightsizing and Standardization Ensures Flexibility, Efficiency, and Repeatable Process Control

By David Olson, Verisurf Software Inc.

Catamount’s focus is on mission-critical industries where every part that leaves the shop must perform flawlessly, often under extreme conditions.

In a fast-paced, high-precision world of advanced manufacturing, the ability to deliver reliable quality, repeatable results, and efficient output isn’t just advantageous – it’s mission-critical. Catamount Machine Works, located in Plant City, Florida, is one such company thriving on this foundation. Since its founding in 2005, the shop has earned a reputation as a precision manufacturing partner that delivers value far beyond the quoted job. For Catamount, success is driven by three principles: rightsizing, standardization, and digital integration.

“We know who we are and what we do best,” says Chris Basgall, owner and Chief Executive Officer of Catamount Machine Works. “Not every job is right for every shop. One of the biggest mistakes a shop can make is saying yes to work they can’t deliver on efficiently or at the quality levels required.” It’s a candid observation, one that defines Catamount’s long-term vision for manufacturing excellence.

A Strategic Evolution

The company’s evolution was organic in its early years, but under Chris Basgall’s leadership since 2020, Catamount has undergone a strategic transformation. Chris brought with him an extensive background in supply chain management, including 15 years of leadership experience in the global telecommunications industry. When he sought to purchase a machine shop that would provide a better work-life balance for him and his family, Catamount quickly stood out.

“The shop had a great team in place, solid foundational equipment, and a culture I could build on,” Chris recalls. From there, he implemented a three-phase strategy: stabilize and enhance operations in the first three years, scale productivity in years four and five, and begin development of their own product by year six.

That structured approach is now ingrained in the business. Phase one involved investing in critical technology upgrades and obtaining certifications essential for working with tier-one OEMs, including AS9100, ITAR registration, and CMMC 2.0 compliance. Safety and environmental upgrades included shop-wide LED lighting, a security system, and an advanced air filtration system that exceeds OSHA standards tenfold.

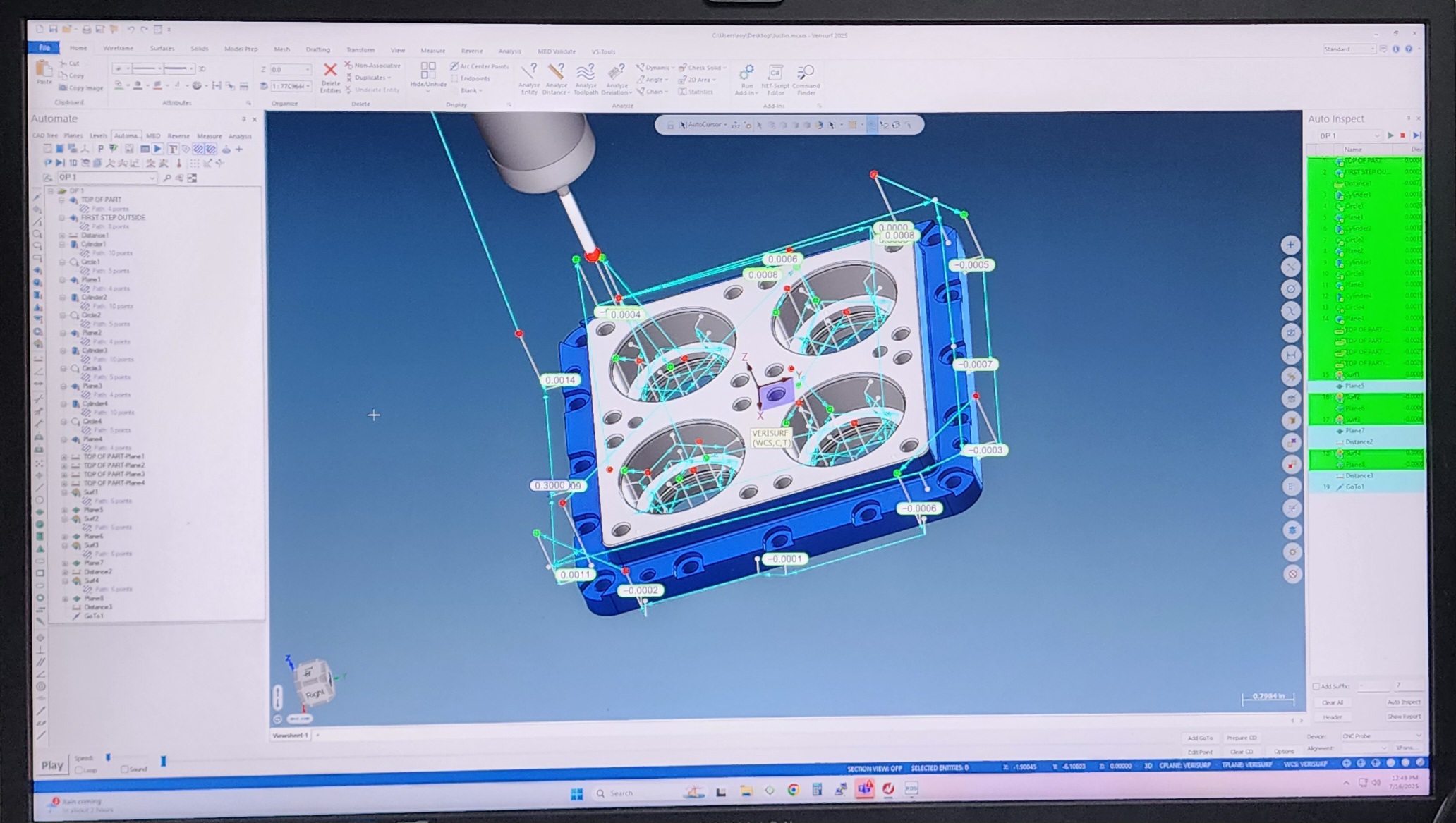

With Catamount’s standardized approach to equipment and software, it is easy to maintain a digital thread from CAD to CAM to CAI (Computer-Aided Inspection). Verisurf's no-code inspection planning, coupled with universal sensor and CAD compatibility, makes quality verification fast and easy.

In phase two, Catamount focused on improving throughput and productivity without compromising quality. This included investing in automation, implementing Six Sigma principles, conducting a comprehensive SWOT analysis, integrating digital workflows, initiating a Kanban inventory system, and reimagining its quality verification process using Verisurf software. These strategies and tools work together to streamline operations and ensure high levels of process control.

Precision Across Diverse Sectors

Catamount specializes in the production of small to medium-sized parts, often made from hard-to-cut materials, for industries where tolerances are tight and reliability is non-negotiable.

These include:

- Aerospace – Components for aviation and spaceflight

- Defense – Systems related to missile guidance and military arms

- Marine – Parts for submarines and underwater communication

- Commercial & Industrial – Applications in automotive, medical, and industrial repair

This focus on mission-critical industries means every part that leaves the shop is expected to perform flawlessly, often in extreme conditions. “Precision and repeatability are baked into everything we do,” says Chris. “If we can’t make it right the first time, we won’t make it at all.”

Rightsizing for Success

A key to Catamount’s success has been “rightsizing” both its customer base and internal processes. Rather than trying to be all things to all customers, the shop focuses on projects that align with its capabilities and offer mutual value.

A key to Catamount’s success has been “rightsizing” both its customer base and internal processes. Rather than trying to be all things to all customers, the shop focuses on projects that align with its capabilities and offer mutual value.

This includes a disciplined approach to job quoting, work acceptance, and customer engagement. “Shops that don’t operate this way are destined to mismanage customer expectations,” Chris warns. “We would rather turn down a job than take it and risk underdelivering.”

Rightsizing also applies internally, matching investments in technology, training, and workforce development with the right scale of operations. This ensures that growth is sustainable and that the quality never takes a back seat to output.

Standardization: The Foundation of Efficiency

Standardization is another strategic pillar at Catamount. The company has deliberately unified software, hardware, and training protocols to ensure every machine, operator, and process speaks the same language.

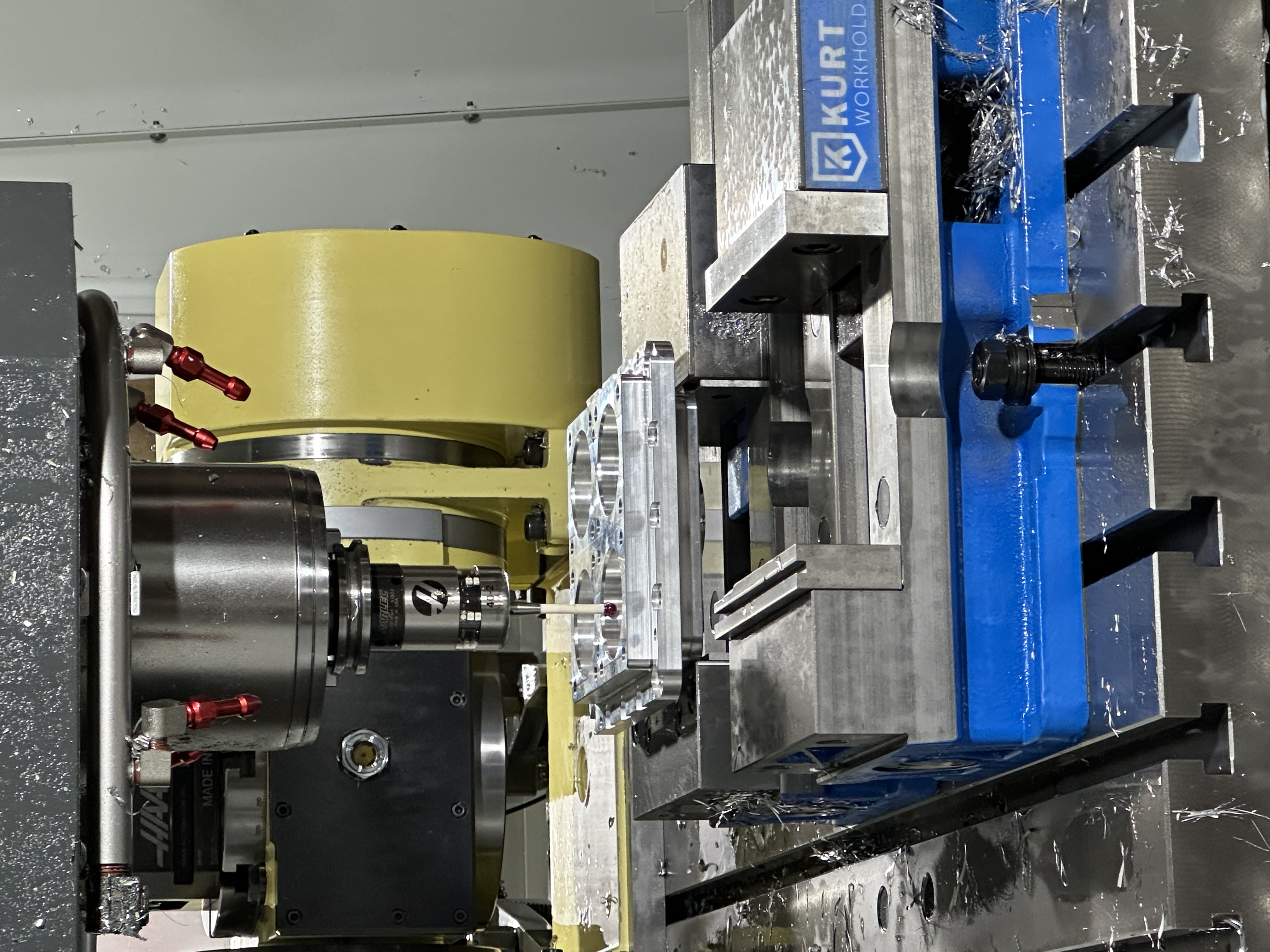

Catamount’s machine tool selection reflects its philosophy of standardization and practical capability. Milling is standardized on HAAS CNC equipment, including lathes and mills in both 3- and 5-axis configurations. CAD/CAM software is standardized on Mastercam. Metrology software is standardized on Verisurf, which is built on top of Mastercam. For Catamount, metrology applies to quality inspection and reporting, tool building, and reverse engineering.

For all CAD/CAM programming, the shop relies on Mastercam – a globally trusted platform that is not only powerful and versatile but also accessible for recruiting and training new machinists.

On the quality side, Catamount has standardized on Verisurf software for all measurement, inspection, and reporting. Verisurf’s key advantage lies in its seamless integration with Mastercam, creating a closed-loop system that connects design, manufacturing, and verification. This digital thread enables Catamount to maintain traceable, repeatable processes and improve communication across departments and with customers.

An inspection plan can be created once and repurposed on any CMM, arm, scanner, or tracker. Productivity tools, including auto-path creation and collision avoidance, support resource management.

Machine Tool Probing Closes the Digital Loop

One of the most powerful aspects of Catamount’s approach is its commitment to closing the digital loop between part design, machining, and inspection. This is where the integration of Verisurf and Mastercam shines.

Because Verisurf is built on the Mastercam platform, Catamount can use a single intelligent CAD model to program machine tools and inspection routines. The same 3D model used to design and machine a part becomes the reference for quality verification, eliminating translation errors and minimizing rework.

The result is a comprehensive digital “fingerprint” of each part that can be archived, analyzed, and shared downstream to SPC (Statistical Process Control) or PLM (Product Lifecycle Management) systems.

This approach dramatically reduces lead times and improves quality assurance. “We’re not just making parts anymore – we’re managing data, repeatable process control, and digital traceability,” explains Chris.

Equipment with Purpose

Catamount’s machine tool selection reflects its philosophy of standardization and practical capability. Milling is standardized on HAAS CNC equipment, including lathes and mills in both 3- and 5-axis configurations. The widespread use of HAAS machines across the U.S. makes it easier to hire experienced operators and secure timely service and support. The shop also has EDM machining centers, CNC grinders, and a variety of other machine tools.

All 3-axis Haas machining solutions in the shop are also equipped for automated probing, operated by Verisurf software. 5-axis probing solutions will be added soon.

“With Verisurf, our HAAS mills become powerful inspection tools as well,” Chris points out. “We can do on-machine probing on all our 3-axis HAAS machines – it’s like having a bunch of CMMs for free.” This capability eliminates bottlenecks at the inspection stage, ensuring that verification keeps pace with production.

Catamount also maintains a Mitutoyo Crysta 574 CMM with a Renishaw PH10 head, operated through Verisurf, and a Master3DGage portable arm for flexible, real-time inspection across the shop floor. Looking ahead, the roadmap includes adding Verisurf 5-axis on-machine probing, a dedicated, programmable CMM, and a non-contact scanning solution to keep quality verification tightly aligned with expanding production.

Master3DGage, Powered by Verisurf Software is a complete portable measurement solution ideal for inspection, reverse engineering, and tool-building. Different jobs require different metrology workflows – the flexibility of the Master3DGage make it a seamless addition in the quality lab, on the shop floor, or out in the field.

Culture of Continuous Improvement

Beyond the technology and strategy, it’s Catamount’s culture that sustains its forward momentum. The team is encouraged to challenge assumptions, refine processes, and identify new ways to improve. Cross-training, peer mentorship, and a genuine respect for craftsmanship are part of daily operations.

Chris fosters a culture of accountability and transparency, where every team member understands how their work contributes to the bigger picture. “We’re building a company that lasts, not just in terms of financials, but in terms of relationships, capability, and reputation,” he says.

Looking Ahead: A Product of Their Own

The final phase of Catamount’s strategic roadmap – now underway – is the development of a proprietary product. While the company remains tight-lipped about specifics, the move reflects the long-term vision of building not just a job shop, but a platform for innovation. By leveraging their refined infrastructure, digital backbone, and engineering expertise, Catamount is well-positioned to bring a unique product to market – one that embodies the same precision, efficiency, and quality that defines their contract work.

Catamount Machine Works is a standout example of what happens when vision, strategy, and execution align. Through rightsizing, standardization, and a deep investment in digital integration, the company has built a resilient, future-ready manufacturing platform.

In an industry where many shops are chasing volume or stretching into unfamiliar territory, Catamount has taken the opposite approach—doubling down on what it does best, investing in people and processes, and delivering precision results every time.

As Chris Basgall puts it, “We’re not the biggest shop, and we don’t want to be. But when it comes to quality, consistency, and customer satisfaction, we aim to be the best.”

About Catamount Machine Works

Founded: 2005

Location: Plant City, FL

Facility Size: 15,000sqft

Machines: 5-Axis CNCs, Turning Centers, Wire EDM, Robotics, and Automation

Metrology: Verisurf Master3DGage, Mitutoyo Crysta 574 CMM, HAAS Machine Tool Probing

Key Software: Mastercam, Verisurf Measurement, and Inspection Software

For more information, visit https://www.catmw.com/home or https://www.verisurf.com/