Advanced Integration

Technology (AIT)

Where High Precision Meets Critical Thinking

Jamie Kempen, Quality Manufacturing Systems Manager

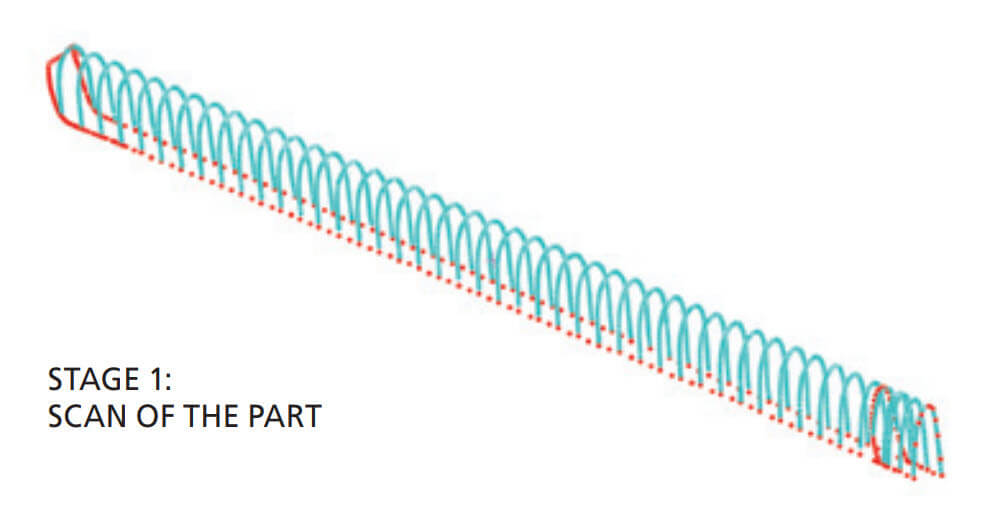

Verisurf Measure software is used to 3D laser scan and create a 3D point cloud of the original rotor blade.

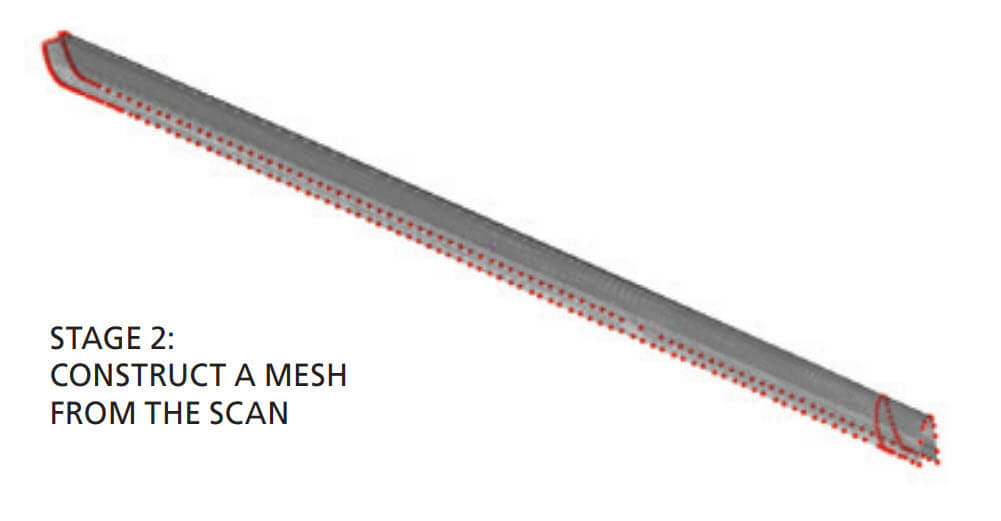

Verisurf Reverse software is used to create a 3D triangular mesh surface from the 3D point cloud data.

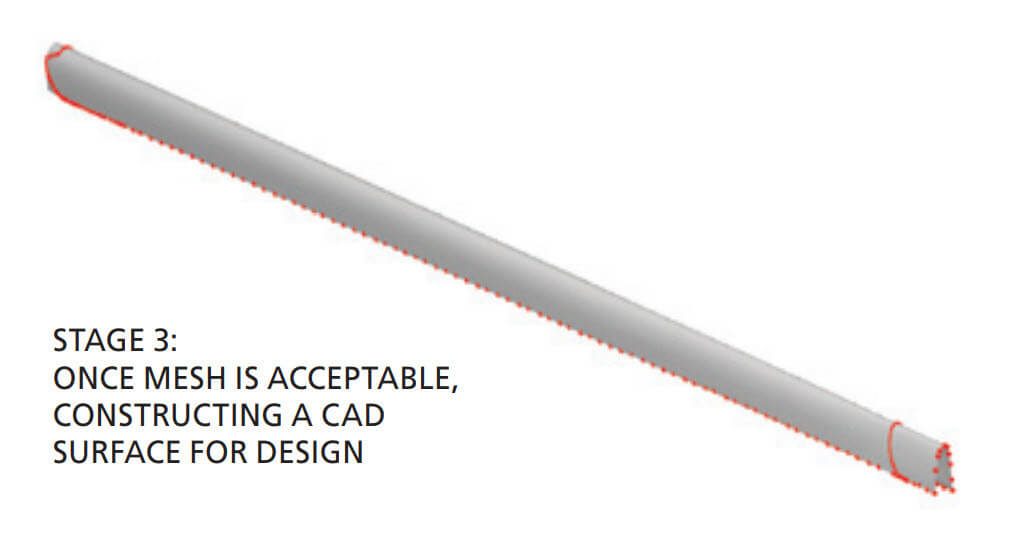

Verisurf Reverse software is used to create a 3D CAD model from the 3D mesh surfaces.

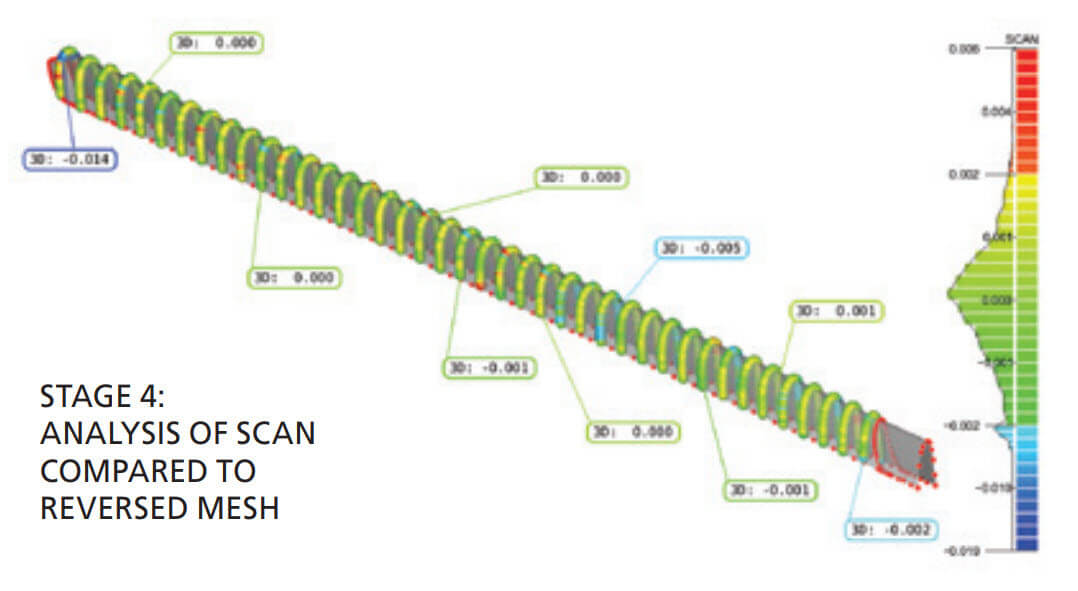

Verisurf Analysis software is used to compare and validate the reverse-engineered CAD model to the original 3D-scanned point cloud.

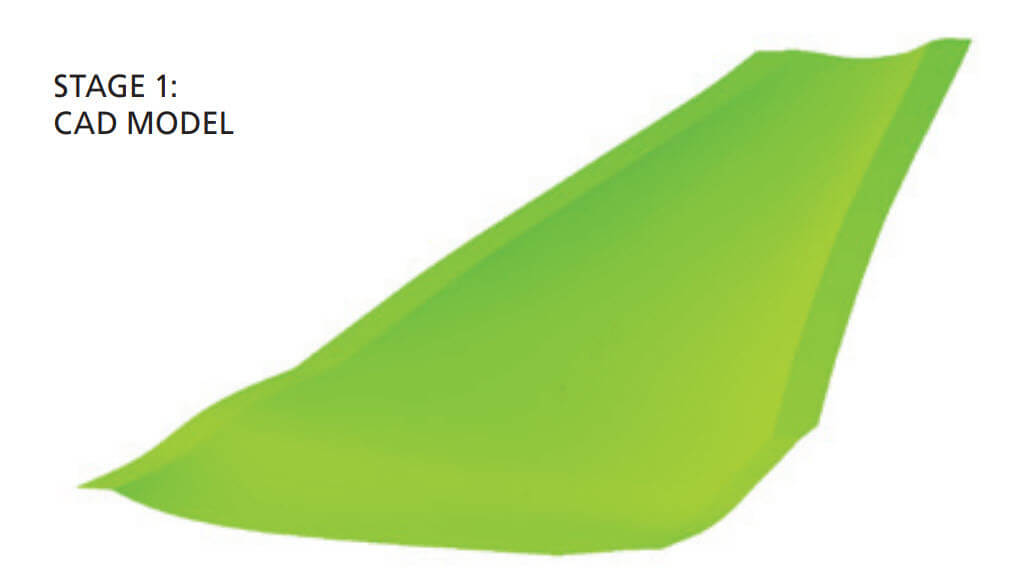

The original CAD data imported to Verisurf Software for analysis.

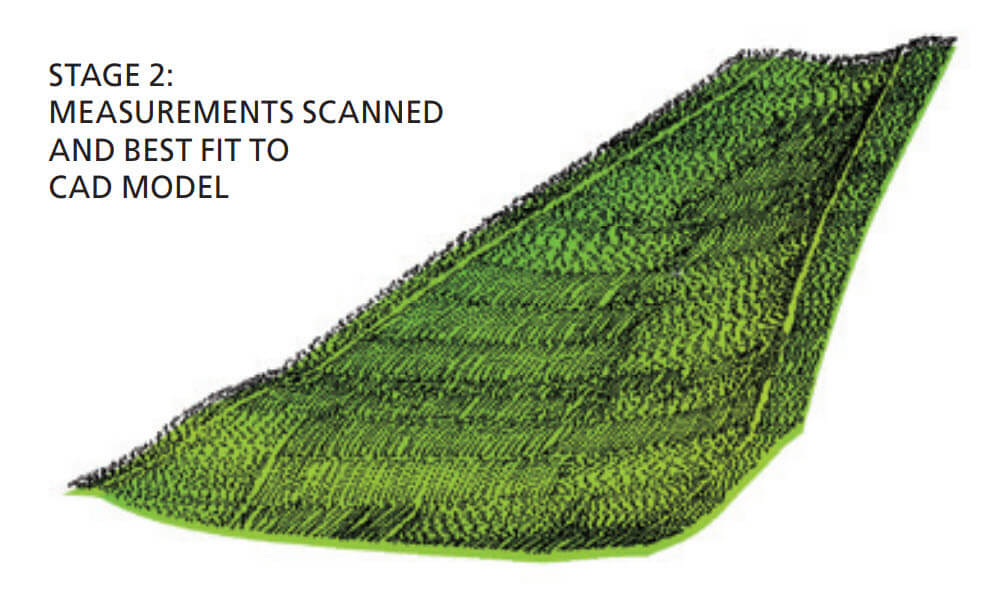

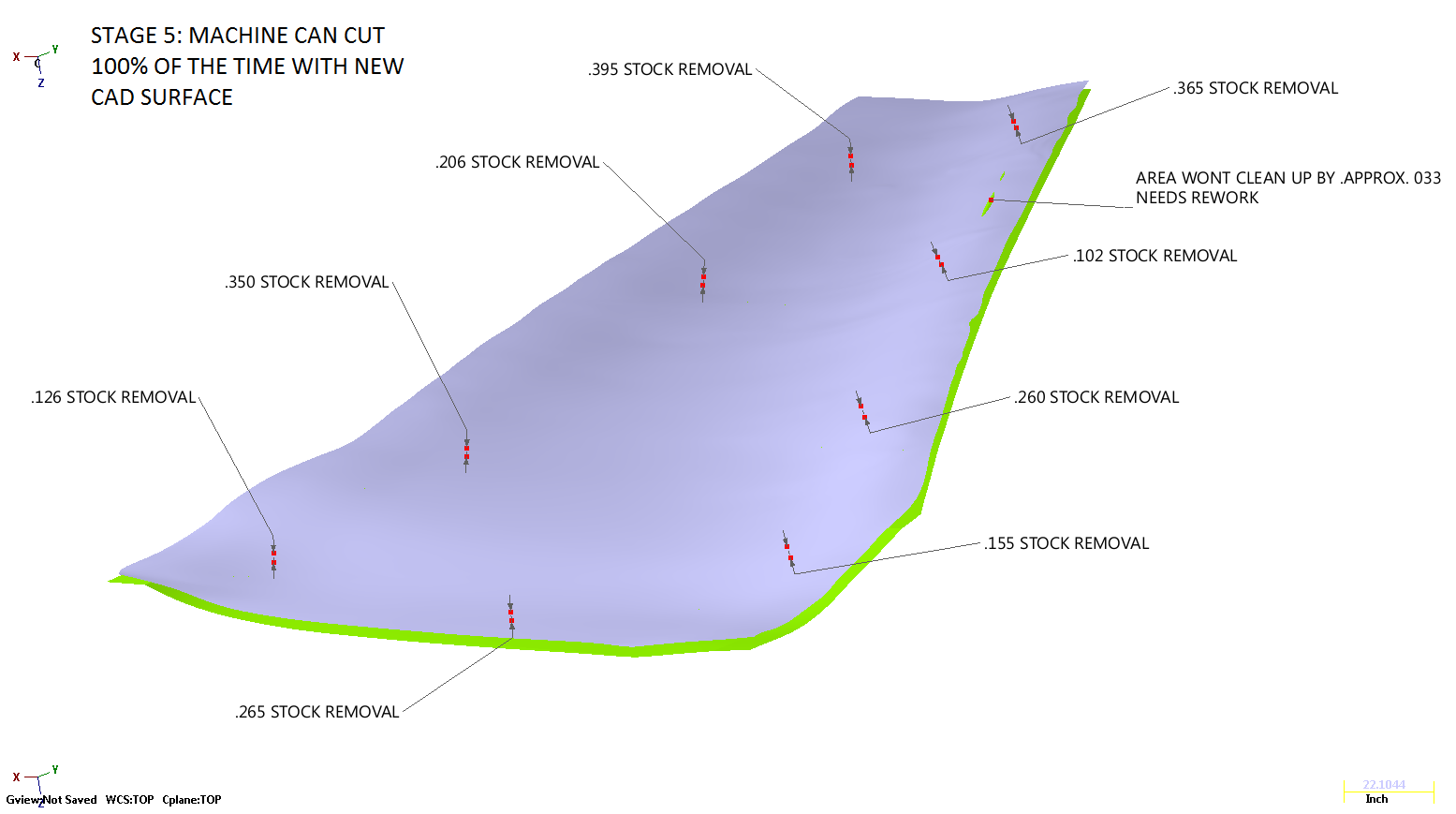

Verisurf Measure software is used to 3D laser scan the as-built tool surface and create a point cloud.

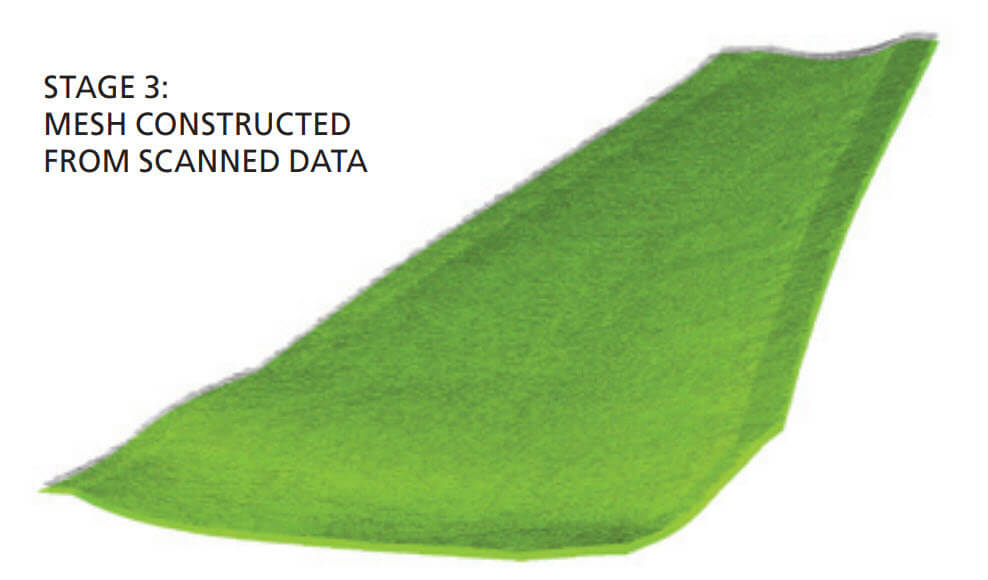

Verisurf Reverse software is used to create a 3D mesh surface from the 3D point cloud.

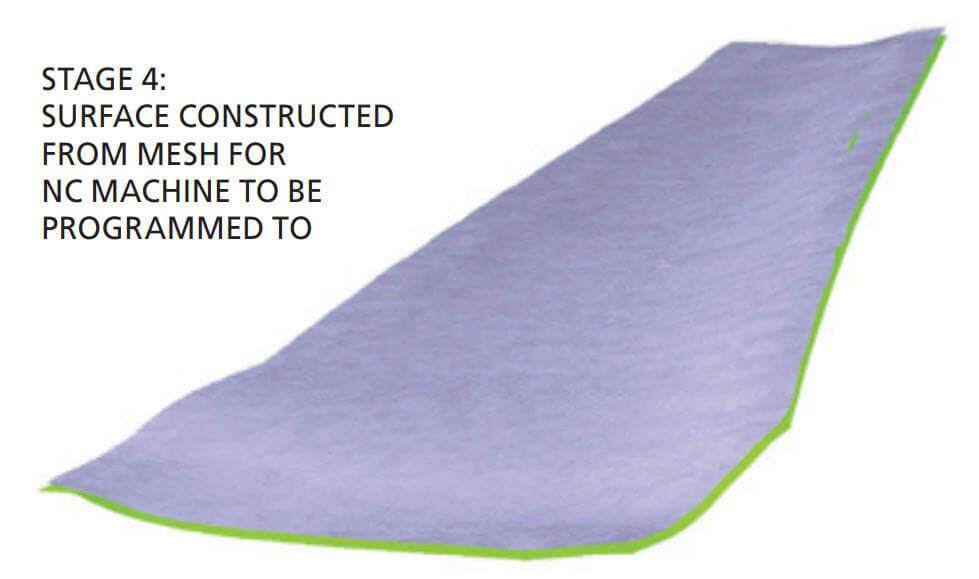

Verisurf Reverse is also used to create machinable 3D CAD surfaces from the 3D mesh surfaces.

“Verisurf software is a useful tool. In our business the final inspection is the easy part, the development and manufacturing processes are filled

with critical thinking – Verisurf supports that thinking. They make my job easier.”

Jamie Kempen, AIT

AIT is a leading industrial automation company specializing in aerospace manufacturing solutions. Their customer list reads like a who’s who of the aerospace industry, including Airbus, Boeing, Bombardier, British Aerospace, CASA, EADS, EDO Corp.,

Watch a video about Advanced Integration Technology

Embraer, Fairchild, Dornier, Global Aeronautica, Hawker Beechcraft, Lockheed Martin, McDonnell Douglas, Mitsubishi Heavy Industries, Northrop Grumman, Spirit AeroSystems, and Triumph Aerostructures – just to name a few. AIT’s Chesterfield Two, Michigan facility is tasked with design and fabrication of autoclave mold tooling and assembly jigs used by tier-one aerospace manufacturers. To maintain high precision, it takes exceptional metrology software:

“To say AIT utilizes Verisurf X metrology software would be an understatement; the company relies on the software for virtually every aspect of our development and production workflow,”

Jamie Kempen

Quality Manufacturing Systems Manager

Advanced Integration Technology

A large part of AIT’s business is developing complex autoclave tooling for composites manufacturing. At first glance, the process seems very straightforward and comprehensive. First, the AIT team agrees to dates and deliverables on a per-project basis. Next, they receive engineering input from which they develop the tools, followed by the tool design process. Once approved the designs go to their in-house fabricating department where the tools are machined, assembled, painted and checked for quality using Verisurf X software – easy, right? Not so fast. Let’s back up and take a closer look at Engineering Input and Tool Design.

In today’s high-tech world, you would think engineering data used to design and build assembly tools would be readily available, but it’s not. Either the customer does not provide it, the data has been lost or corrupted, or in the case of a rebuild, the part being replaced is no longer the same spec as when it was new. “At AIT about 90% of our projects are new builds, the other 10% are rebuilds. Sometimes we get CAD data but often we get drawings or just the part being manufactured or assembled. In every case, we need to apply creativity and critical problem solving to arrive at the final solution,” said Kempen. “For these challenges, we like Verisurf software – it’s easy to swim around the software. Verisurf is so dynamic we can take multiple routes to the end result.”

##

U.S. Soldiers from the Army National Guard replace rotor blades on Apache.

Helicopter Rotor Blade

AIT needed to design and build a bond tool for installation of the skin on rotor blade rebuilds. The challenge was after use, the rotor blade envelope changed, compared to when it was originally built. AIT used Verisurf Reverse to reverse engineer the envelop and provide data so they could design and build an accurate assembly tool. Once designed they again relied on Verisurf software to check accuracy during the build process, and for final QC before shipping. “Virtually every tool or jig that leaves this place has a Verisurf inspection report attached to it,” said Kempen.

A large Invar bond tool used for wing layup.

Large-Scale Bond Tools

“Using Verisurf software we are able to save days, even weeks of machining time on large-scale bond tools,” said Kempen. Fuselage and wing skins are large complex surfaces with extreme tolerances. Typically, creating a face sheet that starts out at 1-inch thickness and is taken down to .5-inch will be reduced by less than “.100 with each pass. The machine starts with the high points and works down. In doing this, AIT used to “cut air” for days until the machine finally got down to the uniform layers. Now they use Verisurf to 3D laser scan the as-built tool surface and create a machining model that allows them to cut material 100% of the time. This literally saves days and sometimes weeks of cutting, 24/7.

With the new surface, the CNC machine tool path can now be programmed to cut material 100% of the time, eliminating day and weeks of cutting, 24/7.

Compatibility

AIT uses multiple brands and types of metrology hardware devices but has standardized on Verisurf software partly because it drives virtually every device on the market. “We use almost every function Verisurf has to offer. The software is intuitive and very easy to use,” said Kempen. “We have also realized training efficiencies by standardizing on the common Verisurf platform.”

Final Inspection

“For us, final inspection is the easy part, we use Verisurf in just about every aspect of our business,” said Kempen.

- Reverse engineering parts to design tooling

- Inspection of the egg crate before fitting the face sheet

- Inspection of the face sheet before final welding

- Final inspection before the tool goes out the door

About AIT

Founded in 1992, AIT is a leading industrial automation company delivering fully integrated plant floor systems and tooling to the aerospace industry. We design, engineer, manufacture, and install machines, systems, and tooling for the automated assembly of aerospace structures, including fuselage, wings, and empennage. Relying on the strength of our diverse team of engineering pros, AIT has a leading position as the predominant integrator and prime contractor to the world’s foremost aerospace companies, with hundreds of systems installed worldwide. Learn more at www.aint.com.