Verisurf Introduces Support for Renishaw PH20

Improves Accuracy and Cuts Inspection Cycle Time by 66%

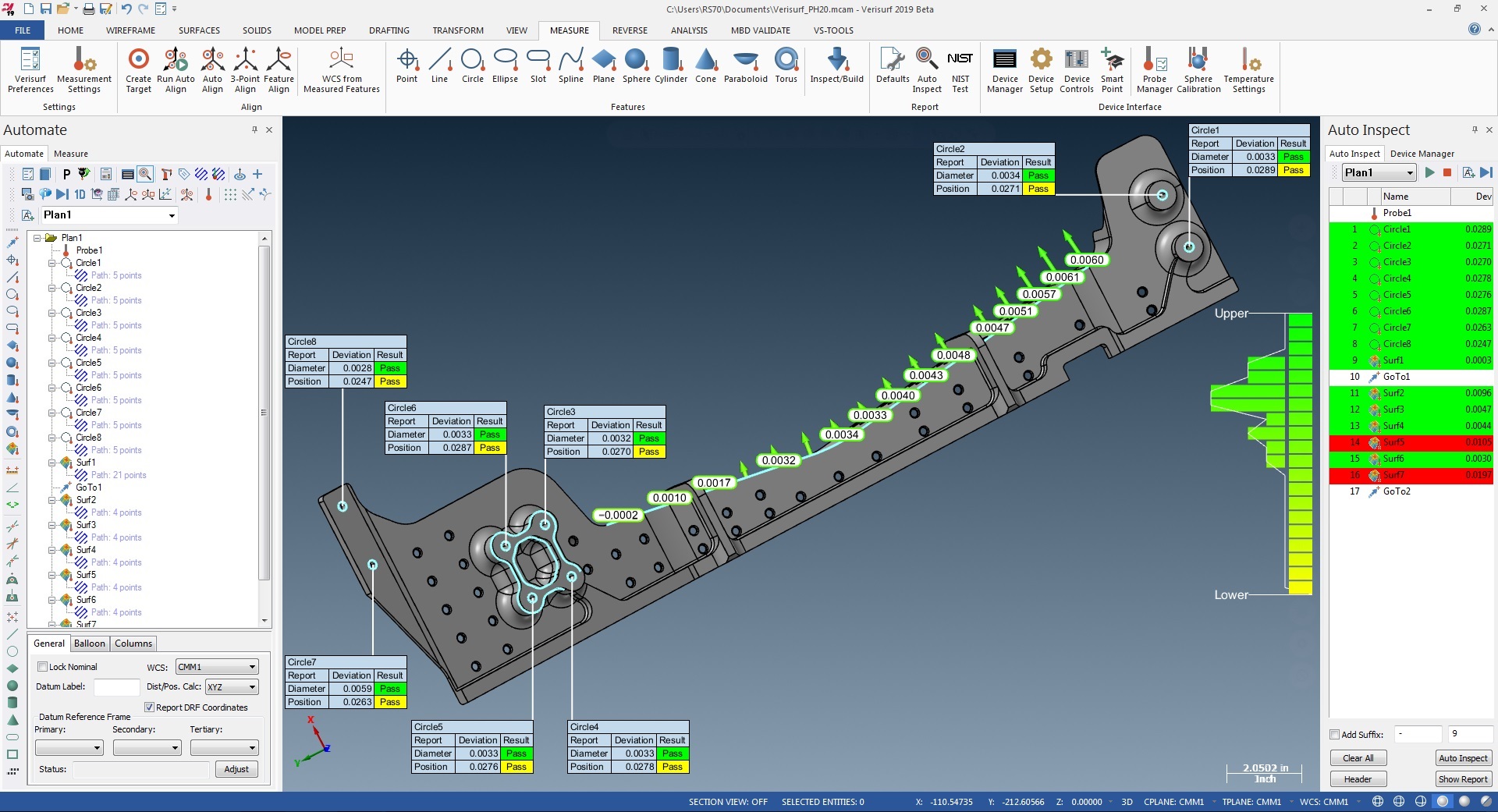

Verisurf software, Auto Inspect panel and feature balloons present real-time deviations of measured features, compared to the CAD nominal.

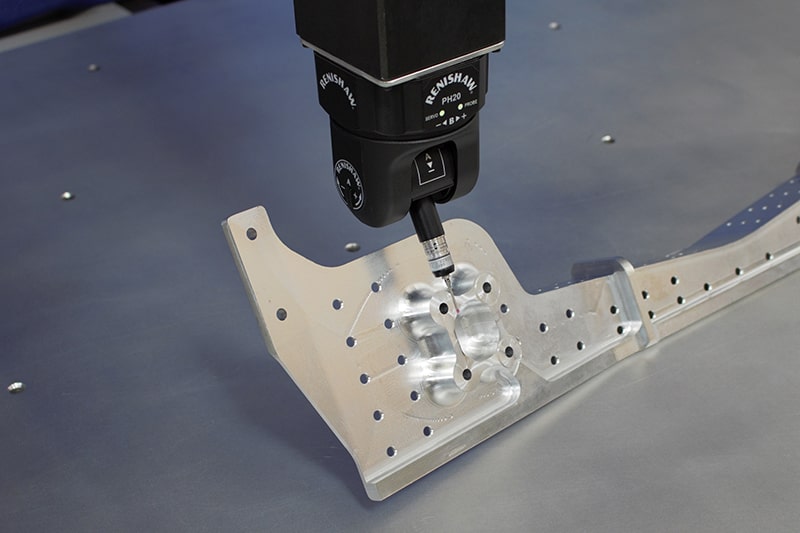

Verisurf software maximizes the capabilities of the PH20, 5-axis probe-head, which reduces the movement of the CMM structure, and eliminates time indexing the head. Measurements can be taken faster with improved accuracy and repeatability.

For Immediate Release

Verisurf Software, Inc. announced device support for the Renishaw PH20, 5-axis probe-head. Verisurf customers running the PH20 currently or planning to retrofit their CNC CMMs will realize the power of Verisurf automated inspection software with the full potential of 5-axis probing. Inspection cycle times are reduced by as much as 3X when probing in 5-axis, compared to traditional indexing heads, without sacrificing accuracy.

“Accuracy, speed, flexibility, and overall efficiency are key factors in today’s measurement solutions. Verisurf software controls measurements from virtually any CMM, a process that is limited only by the mechanical capabilities of the machine. The Renishaw PH20 probe-head is very accurate, and through enhanced motion control, improved touch-trigger, and calibration technology, it allows our software to do more, faster,” said Ernie Husted, President and CEO of Verisurf.

Verisurf CMM programming software and the PH20 5-axis probe-head are used to maximize inspection throughput on new or existing CMMs with Renishaw controls. In addition to the enhanced measurement data collection, Verisurf software CAD model-based productivity features speed up the quality inspection and reporting process. Easy object-oriented CMM programming tools quickly create automatic inspection and quality reporting routines, and during inspection, an Auto Inspect panel and feature balloons present real-time deviations of measured features compared to the CAD nominal.

“Support for the PH20, 5-axis probe-head demonstrates Verisurf’s commitment to universal compatibility, providing a common inspection and measurement platform for the total manufacturing enterprise,” added Husted. Using CAD models with associative GD&T, users can quickly create a single inspection plan that can be implemented across all measuring devices, regardless of type or brand, including new and legacy equipment.

Verisurf Software, Inc.

Verisurf Software, Inc. is a measurement solutions company, committed to delivering advanced surface analysis, quality inspection, assembly guidance, and reverse engineering. Verisurf products and processes are vital to maintaining a digital thread between design, engineering, manufacturing, and finished part validation. Based on a powerful CAD platform, Verisurf is committed to digital Model-Based Definition (MBD), open standards, and interoperability with all coordinate measuring machines and CAD software. Verisurf solutions help manufacturers produce higher quality products in less time. For more information visit https://verisurf.com.