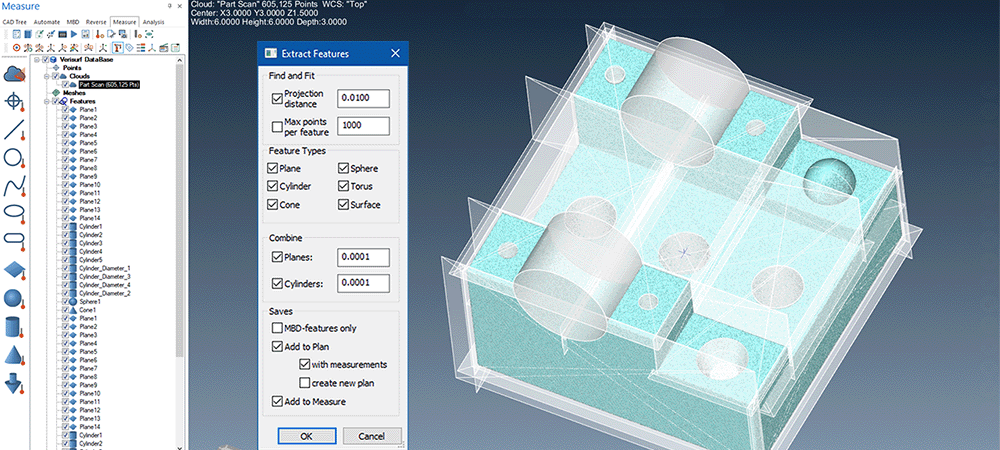

Simplifies plan creation through automatic extraction of features from clouds and meshes:

Scott KnocheAugust 1, 2023

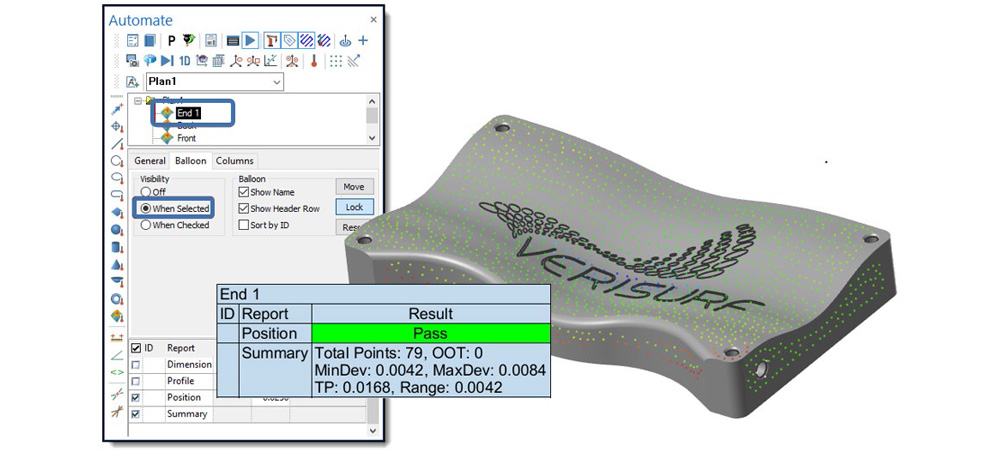

Verisurf AUTOMATE features for setting up reports and balloons in your CMM program:

Scott KnocheJuly 18, 2023

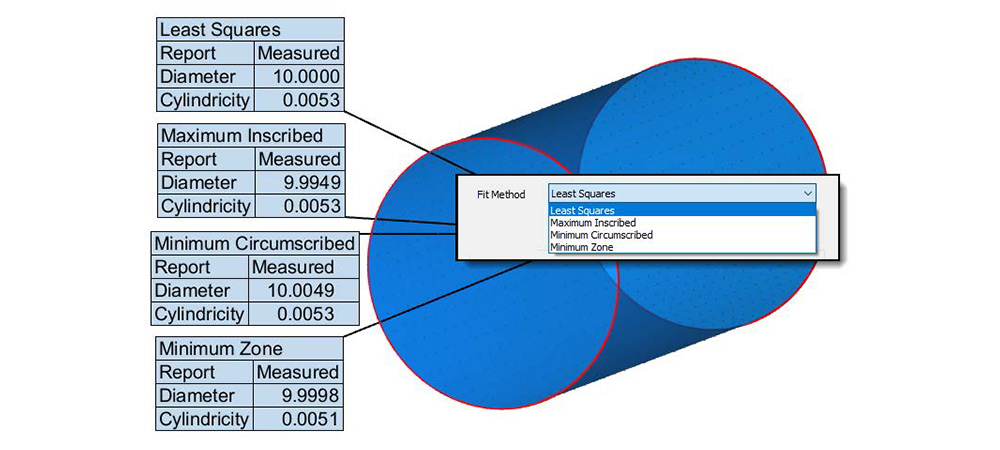

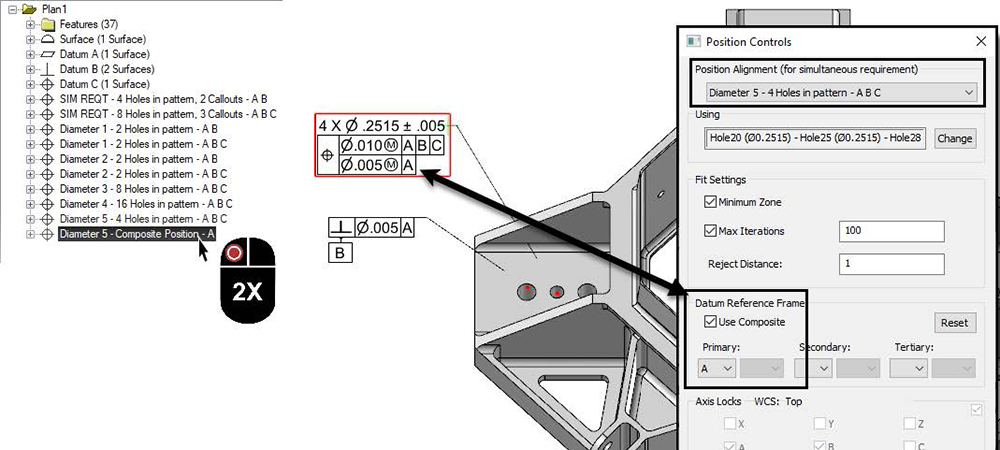

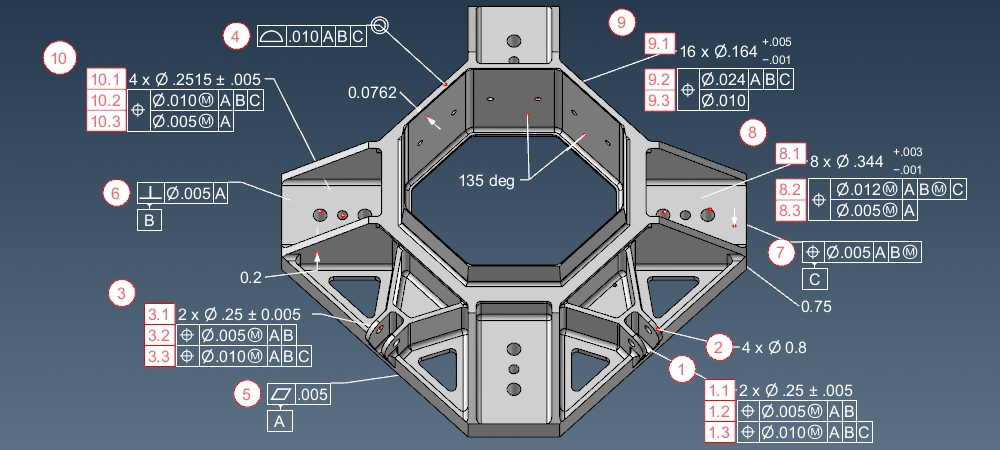

Enhanced GD&T analysis through datum modifier support for Position and Profile with advanced options for Composite Position.

Scott KnocheJune 26, 2023

Automatic addition of first article inspection balloon IDs from CAD MBD/PMI:

Scott KnocheJune 19, 2023