Hexagon Absolute Tracker Powered by Verisurf Tool Building & Inspection Software

THE COMPLETE SOLUTION

Tool Building and Large Volume Inspection with Hexagon Absolute Laser Tracker Powered by Verisurf Tool Building and Inspection Software

The Hexagon Absolute Laser Tracker AT960, powered by the Verisurf Tool Building & Inspection Suite and training services, is a complete metrology solution that provides efficient, computer-aided tool-building for medium-to-large scale inspection applications.

Verisurf’s laser tracker productivity starts with its easy-to-use CAD/CAM experience featuring intelligent MBD that speeds measurement planning while tracker interaction is optimized with unique device settings, free mobile phone app, watch app, and CTE app, and highly repeatable inspection plans for unparalleled quality process control.

Whether you are inspecting, building tools, or reverse engineering, Verisurf gets the best performance from the AT960!

Realize higher productivity with an AT960 Powered by Verisurf:

- Ideal for large volume, high precision alignments, guided assembly and repeatable inspections.

- Solo operation optimized with powerful settings and mobile applications.

- Verisurf Tool Building & Inspection Suite delivers rapid return on investment.

- Custom training for fast implementation, with annual updates and technical support to keep production going.

AT960 Laser Tracker Basic Specifications

- Up to 80 meter measurement range

- Reflector single-point accuracy to within 20 microns

- The Absolute Interferometer (AIFM) combines the accuracy of an absolute

distance meter (ADM) with the speed of an interferometer - PowerLock automatic beam-targeting set a new standard for quickly acquiring, locking on, and target following by the laser beam

- Built-in WiFi communication

- Sealed and IP54-rated for operation in adverse environments

- Optional non-contact, 3D laser scanner and 6DoF (six degrees of freedom) probe for quick and accurate non-line-of-sight measuring

Popular High-Tech Options for the AT960 Laser Tracker

Absolute Scanner AS1

Flagship high-speed blue laser 3D scanning performance with IP54 protection. Available in two versions: Standard FOV (field-of-view) with high accuracy and large FOV with high standoff and high scan rate. Whether faced with glossy black plastic automotive body parts or molded carbon-fiber components, the innovative algorithms allow the AS1 to scan with no reduction in quality or productivity.

T-Probe

The T-Probe is a completely wireless solution for the probing of hidden and hard-to-reach points. With minimal setup times and station changes combined with a high point acquisition rate, automatic stylus recognition, and individually assignable multi-function buttons, the T-Probe is the key to high-productivity single-point data capture.

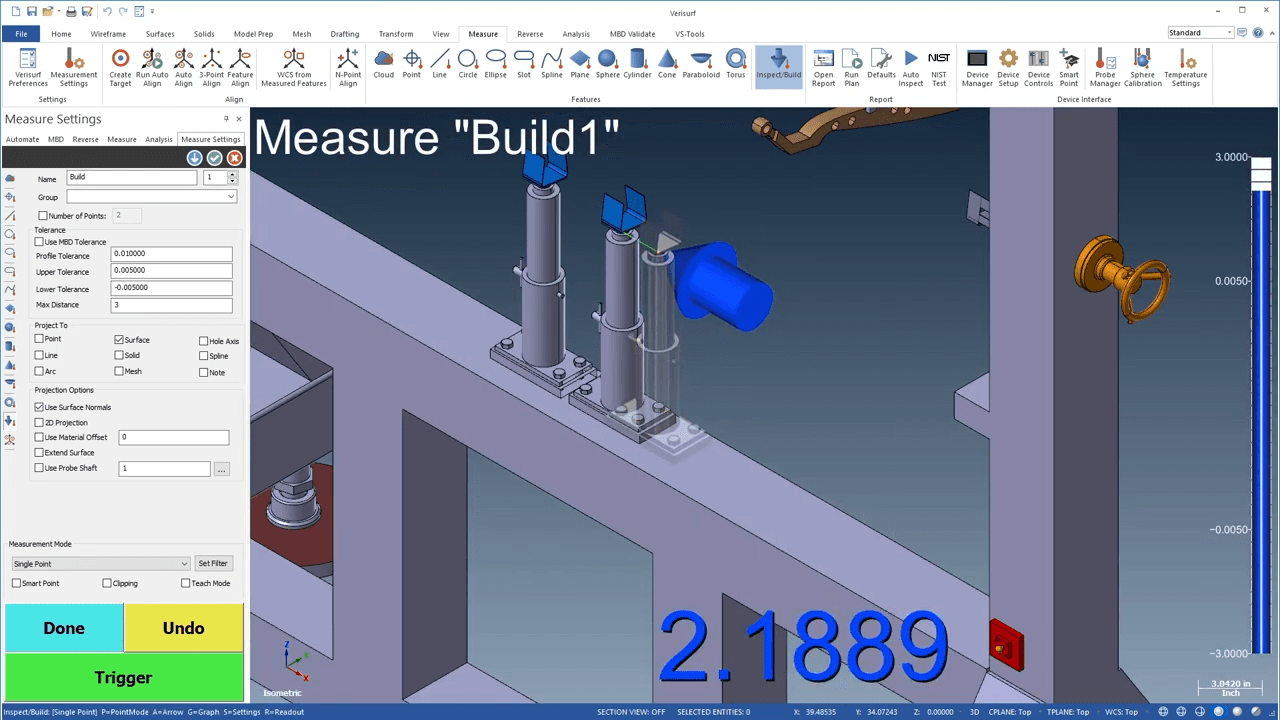

Verisurf TOOL BUILDING & INSPECTION SUITE

- Quickly and accurately set tooling details with real-time “build-to” computer aided assembly to CAD

- Adjust, shim, ream, and perfect the assembly followed by instant QC inspection report of the completed job

- The integration of CAD and metrology reliably connected to tool-building is a worldwide standard set by Verisurf

- Widely recognized as the standard of excellence for tool building at most major aerospace and automotive manufacturers

- Several live, color-coded graphical and sound feedback indicators keeping the operator informed and alerted to measurement and compliance conditions

- Easily report valuable detail with multi-color clarity of measurement results

- The fastest align-inspect-report workflow available

- Memorize steps to create reusable plans for repetitive jobs and process control

- Embrace model-based definition (MBD) with “interactive GD&T” imported from native CAD or self-applied, then automatically employed by the software for real-time application in measuring and reporting

- Direct, fast import of all major CAD file formats including massive files with ease

- Qualified, aerospace CAD file translation validation

- Fast and simplified drift monitoring and reporting

- CTE compensation, monitoring, and reporting with customizable temperature alarm

- Device station moves made fast and easy with Auto Align and intuitive bundling

Free mobile apps available to assist tool building tasks:

VS Companion

Take advantage of wireless mobility and touchscreen gestures to run inspection plans fast with the Verisurf Companion App

Click Here to Learn More

VS Watch

Enjoy greater mobile measurement agility with the convenience of hands-free DRO monitoring on Apple Watch or WatchOS devices

Click Here to Learn More

VS CTE

Quickly determine change in length for common manufacturing materials due to temperature effects with the VS CTE app for Android

Click Here to Learn More

Verisurf Training & Support Services

Verisurf live training classes are taught by experienced dimensional metrologists skilled in the application of CMMs, portable CMM arms and laser trackers, scanners, and Verisurf to a wide variety of 3D measurement applications including: inspection automation, tool building, 3D scanning and reverse engineering.

Verisurf instructor-lead training classes are customized to each customer’s applications, parts, processes and people and are held either at the Verisurf corporate training center or at a customer facility.