Scanning & Reverse Engineering with Hexagon Absolute Arm Powered by Verisurf Software

THE COMPLETE SOLUTION

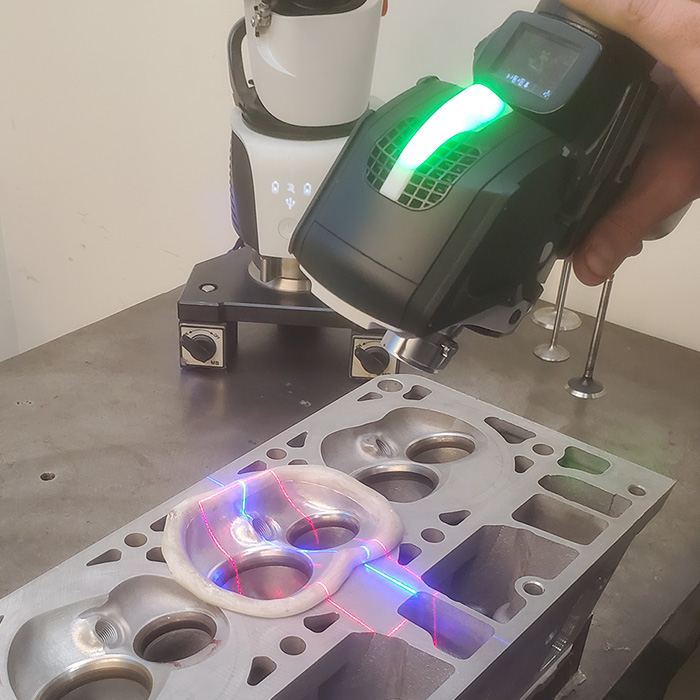

Reverse Engineering with Hexagon Absolute Arm & Scanner and Verisurf Software

The Hexagon Absolute 7-Axis Scan Arm powered by the Verisurf 3D Scanning & Reverse Engineering Suite of software, is a complete metrology solution for a quicker path to an accurate, fully complete, 3D CAD model of a manufactured part. Verisurf software takes the Hexagon Arm & Scanner to its highest level of efficiency by providing a vast suite of tools that minimizes the often challenging tasks involved in digitizing a complex part.

Big Benefits

- Portability allows for the job to be done where it works the best for any given unique scenario

- Instantly swap between probe and scanner, no need to install or remove either and no need to calibrate.

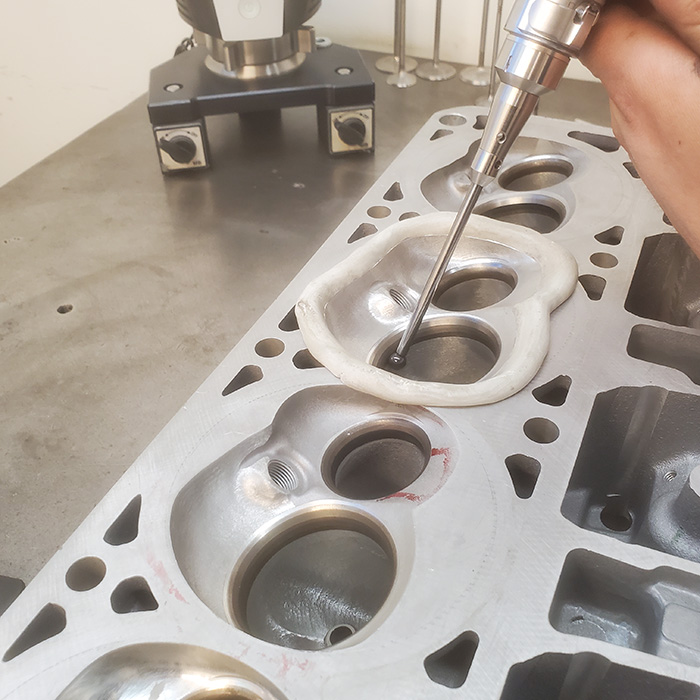

- With the hard probe, measure dimensions and locations of recessed features, including critical hole and slot positions.

- Select scanner mode for super-fast data capture and obtain complete coverage, including contours, fillets, blend radii, and all exposed features.

- Iterate through the workflow to ensure accuracy by checking digitized features and surfaces using Verisurf’s real-time Inspect and offline Analysis features.

- Flexibility to accommodate all types and sizes of objects.

- Ensure success with Verisurf’s custom training as an essential piece of the complete solution.

Absolute 7-Axis Scan Arm Basic Specifications

- Carbon fiber tubing provides high strength, superior stiffness, and thermal stability

- “Zero-G” counter balance and low fatigue ergonomics

- Multi-function control buttons with onboard OLED display

- Hot-swappable probes, ready to measure without stopping to calibrate

- Standard probes included plus endless custom probe capability

- Wireless, battery operation included for true portability

- “Smart Lock” protects the arm in stowed position

- Sealed and IP54-rated for operation in adverse environments

Absolute Scanner AS1

Flagship high-speed blue laser 3D scanning performance with IP54 protection. Available in two versions: Standard FOV (field-of-view) with high accuracy and large FOV with high standoff and high scan rate. Whether faced with glossy black plastic automotive body parts or molded carbon-fiber components, the innovative algorithms allow the AS1 to scan with no reduction in quality or productivity.

RS5 Laser Scanner

Reliable general-purpose 3D scanning.

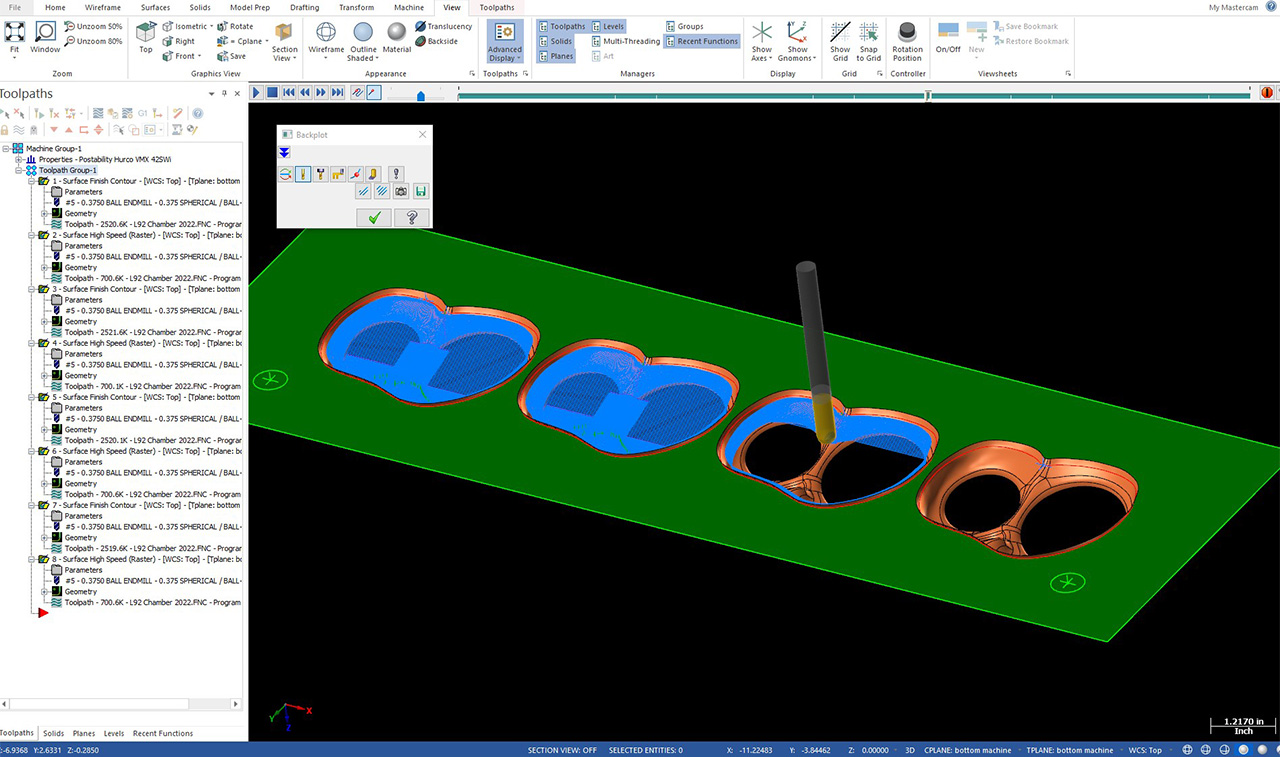

- Full-featured true CAD foundation provides modern design, sketching, and parametric solid modeling

- Robust CAD functionality includes important model organizing capabilities including layers/levels, colors, groups, masks and entity customization

- Automatic and custom drafting dimensional and GD&T/MBD annotation and 2D drawing creation

- Export in industry standard agnostic CAD formats with solids, NURBS surfaces, wireframe, and mesh entity types

- NIST tested math fit any 2D or 3D feature type with fit options (least squares, minimum zone, highest point, inscribe, circumscribe)

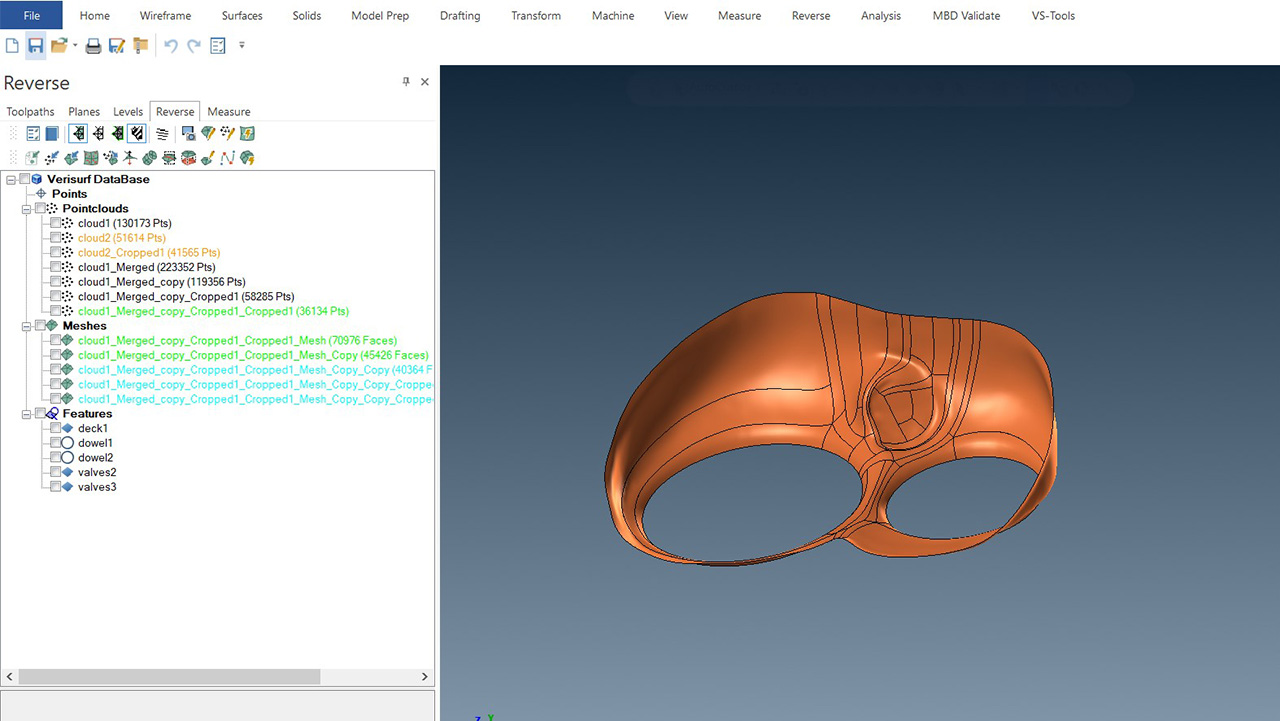

- Capture and model the design-intent (“perfect”) model or the as-built condition

- Automatically “normalize” feature fits to the design intent with time-saving multi-edit

- Create geometric features directly in CAD as they are measured or fit them from points, clouds and meshes

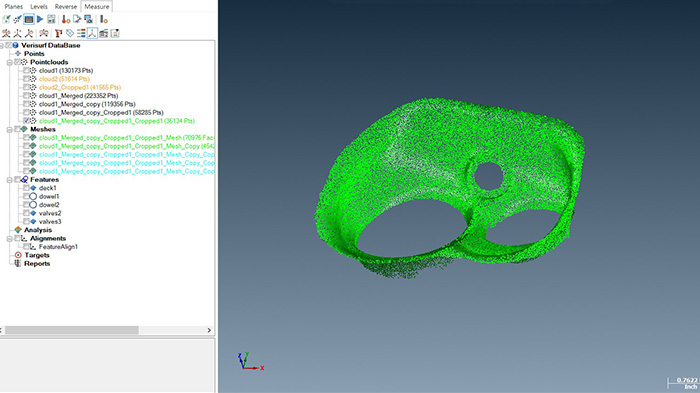

- Register and merge multiple point-clouds or meshes with manual and automatic methods

- Align data to reference frame or coordinate system to facilitate modeling and manufacturing

- Filter and remove extraneous data, smooth, sharpen, refine, and re-mesh parts of the mesh or offset, project, and reverse selected faces

- Optimize meshes by reducing face count while maintaining accuracy

- Quickly and easily extract geometric features from probe or scan data

- Create double-curvature patch surfaces from sparse data

- Surfacing controls with UV control points, curve and point weighting, and surface normal vector control

- Stretch and bend surfaces to conform to the mesh and be trimmed to curves

- Results graphically and numerically displayed in real-time to get the right surface

- Slicing and sketching tools to create curves for surface and solid modeling

- Full solid modeling and ability to finish models with bosses, holes, chamfers, and fillets furnished by Verisurf CAD

- Solids Manager with complete history of modeling operations

- Access underlying wireframe geometry to reflect measurement changes

- Modify operations parametrically and regenerate the solid model

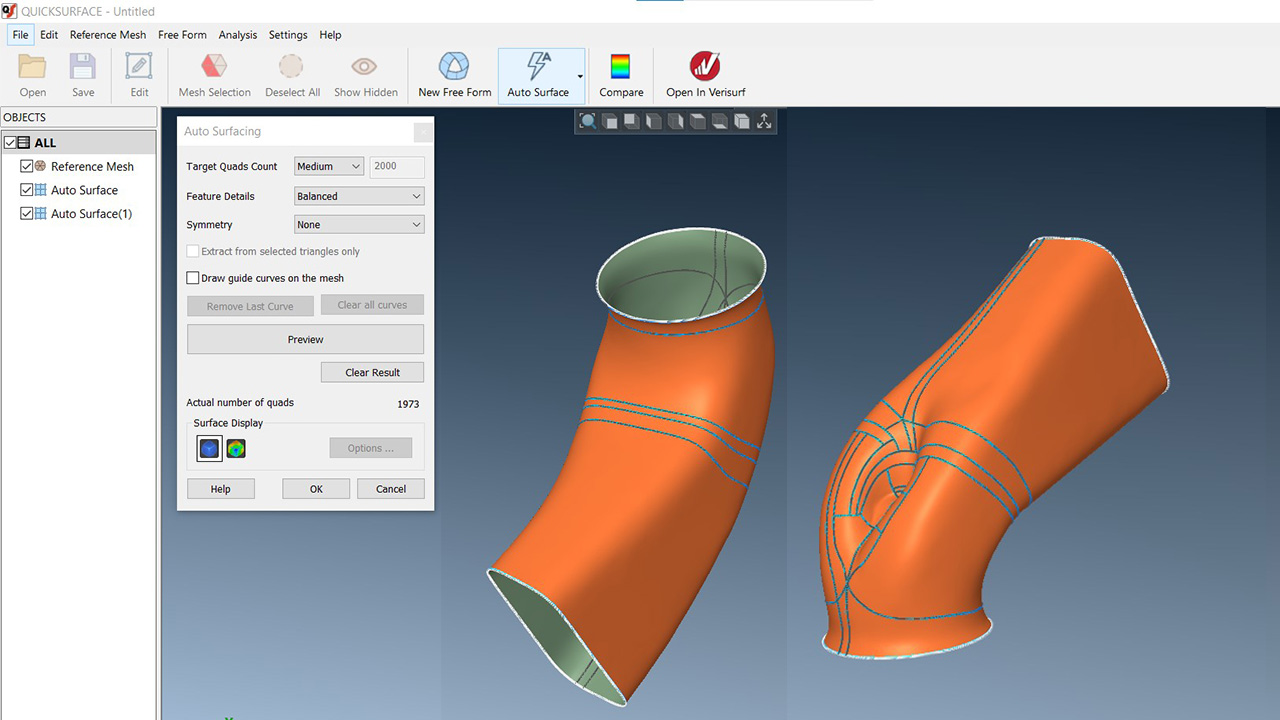

Quick Surface

- Fast freeform NURBS surfaces ready for 3D printing or machining

- Interactive control to visualize and adjust curvature continuity

- Quick surface quality check with fit analysis of surface to original mesh

Verisurf Reverse Engineering Videos Playlist

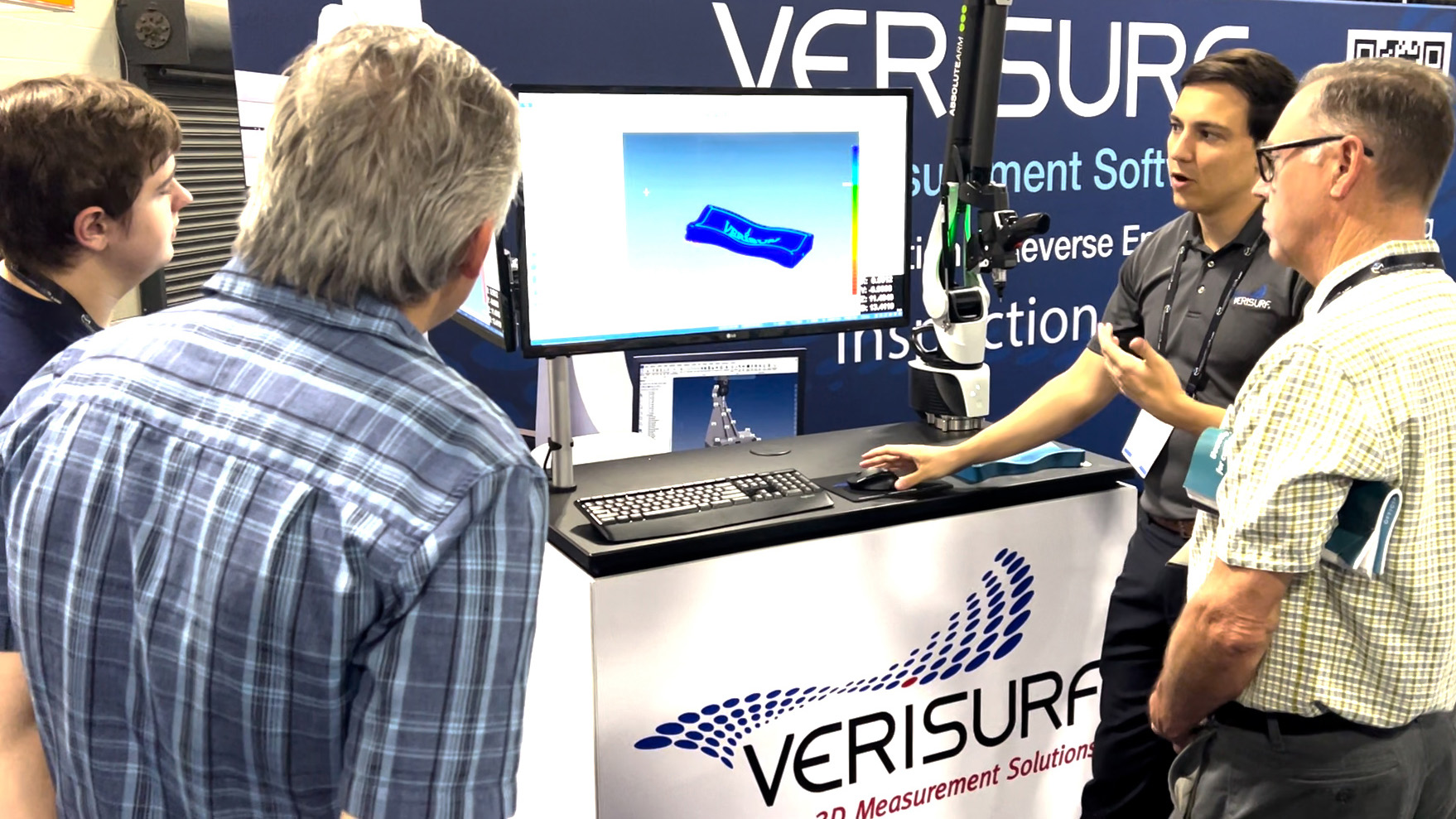

Verisurf Training & Support Services

Verisurf live training classes are taught by experienced dimensional metrologists skilled in the application of CMMs, portable CMM arms and laser trackers, scanners, and Verisurf to a wide variety of 3D measurement applications including: inspection automation, tool building, 3D scanning and reverse engineering.

Verisurf instructor-lead training classes are customized to each customer’s applications, parts, processes and people and are held either at the Verisurf corporate training center or at a customer facility.